News & Media

iSUN3D customized 3D Printing insoles system shines at Rehacare 2019 !

2019-09-24

The German Rehabilitation Exhibition REHACARE, held annually, has a history of more than 40 years and has been the most comprehensive display platform for the latest products in the field of rehabilitation care. It is always committed to helping people live independently and create new opportunities to provide more inclusive and independent rehabilitation assistance.

From September 18th to 21st, [REHACARE 2019] had a successful conclusion at the Düsseldorf Exhibition Center in Germany! 751 exhibitors from 43 countries participated in this wonderful gathering.

The electric wheelchair Scewo Bro is the project of a Swiss student, which is said to be the only wheelchair in the world that combines two-wheel semi-automatic driving and stair climbing function.

Electric devices are very popular at present for people who need help on standing on their own or moving in wheelchairs which are common actions in daily life.

Install a slanting board that can be automatically retracted at the back of the car to help more people get on and off the train;

The Bateo robotic arm allows high paraplegic patients to grab, eat, drink, open the door and even pick up items;

Eichgraben in Austria developed a PC keyboard for disabled partners. Known as TiPY, it can do everything a standard keyboard can do and even more.

With the advancement of technology, rehabilitation care equipment is becoming more and more intelligent. From the operation of picking and unloading to the help of sports competition, from corrective help to nursing prevention, exhibitors showcased a variety of leading technologies in the industry to meet the scientific and technological needs of human rehabilitation care.

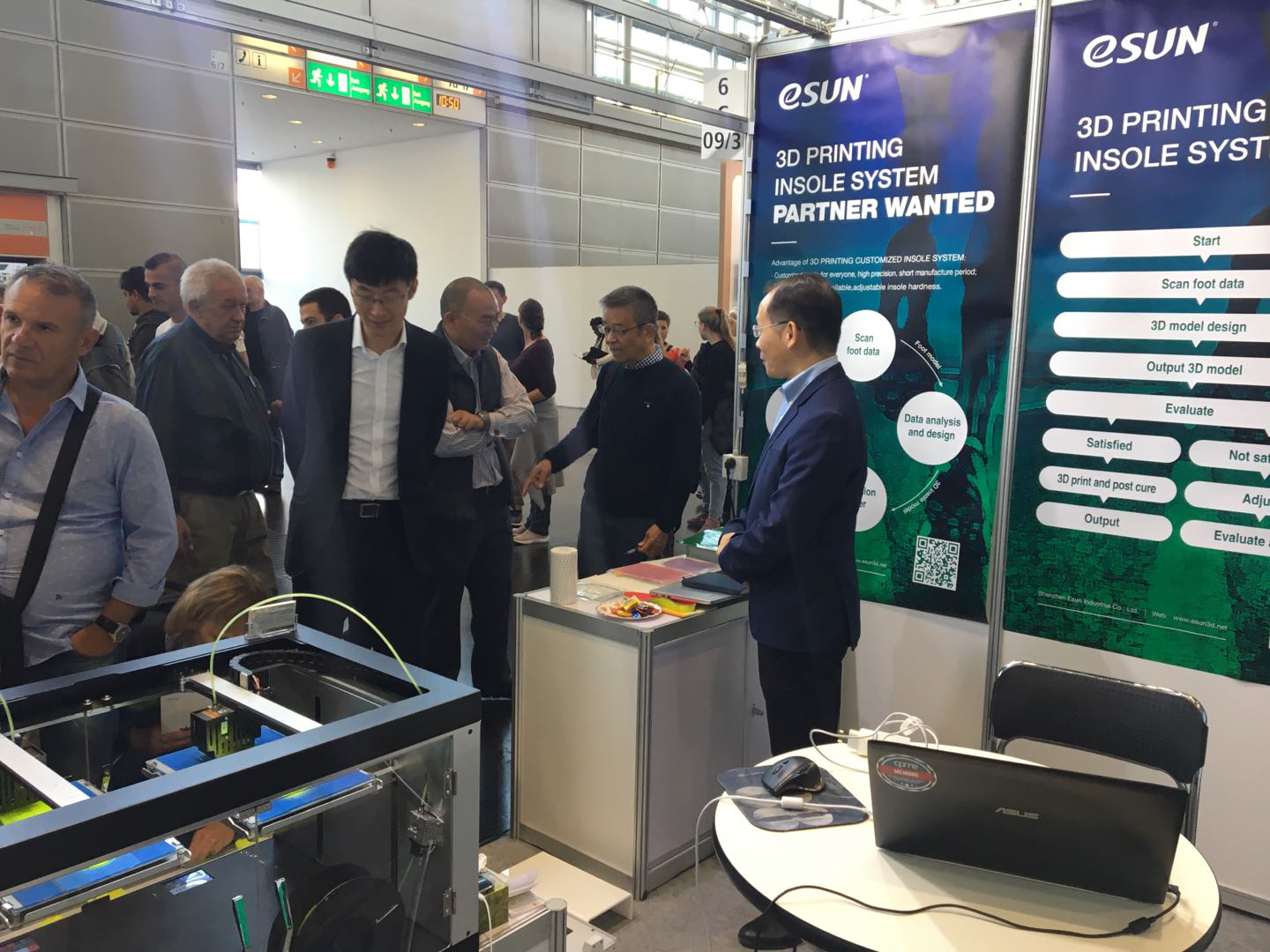

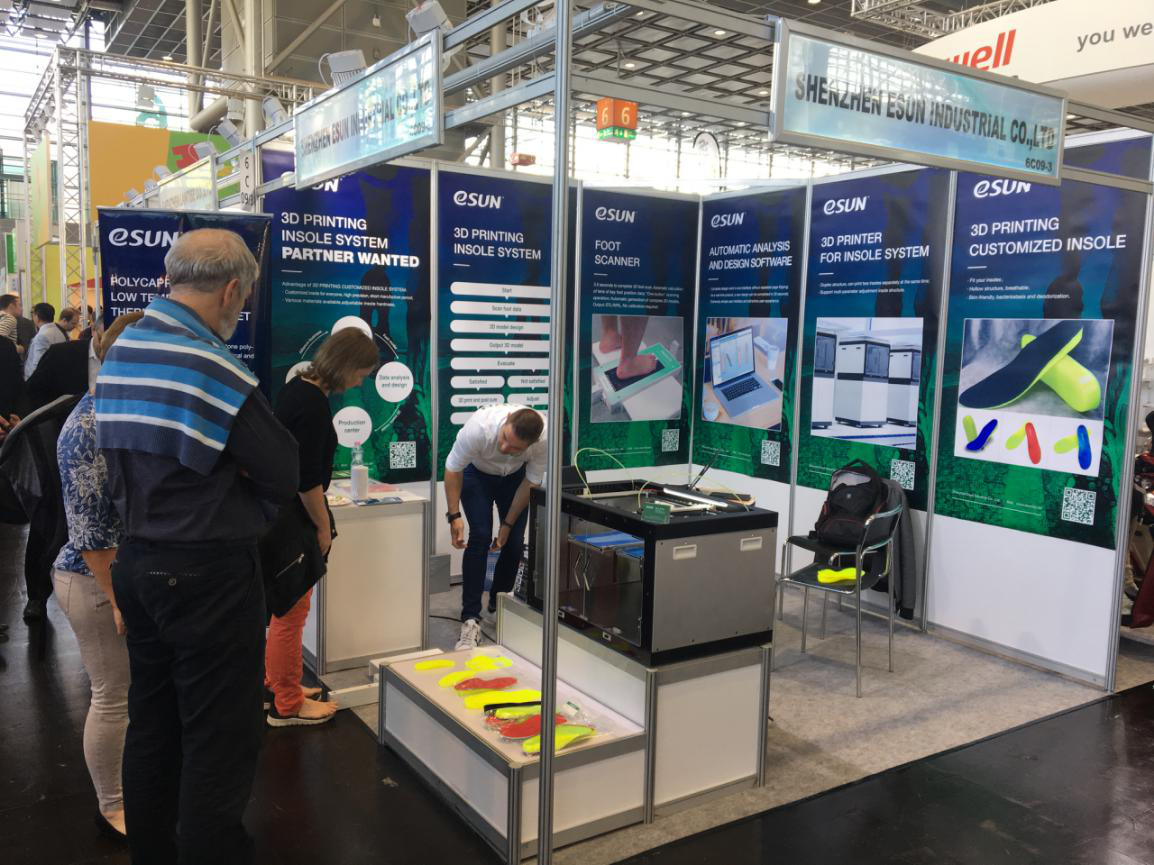

eSUN, a well-known biomaterial brand dedicated to the industrialization of environmentally friendly materials, actively participated in Rehacare. Based on lactic acid production, it has formed three series of products such as lactate, polyol and polymer, all of which concerns on medical. The new iSUN3D customized 3D Printing insole system and function Low-temperature thermoplastic panels, polymer fixed bandages, etc., have been well received.

The main theme of the exhibition is rehabilitation. eSUN is not quite well-known in this field we combines rehabilitation treatment with 3D printing, and people get to understand the brand awareness of eSUN in the global 3D printing field.

Speaking of medical material product, eSUN low temperature thermoplastic plate is a special synthetic polymer polyester treated by a series of physical and chemical methods of new polymer materials; and polymer fixed bandages are processed with imported biodegradable and low-melting polymer resin material in advanced technology, which is an ideal external fixation and orthopedic material for clinical application of orthopedics. These two materials have attracted many European customers and enhanced the awareness of eSUN brand as bio-material manufacturers.

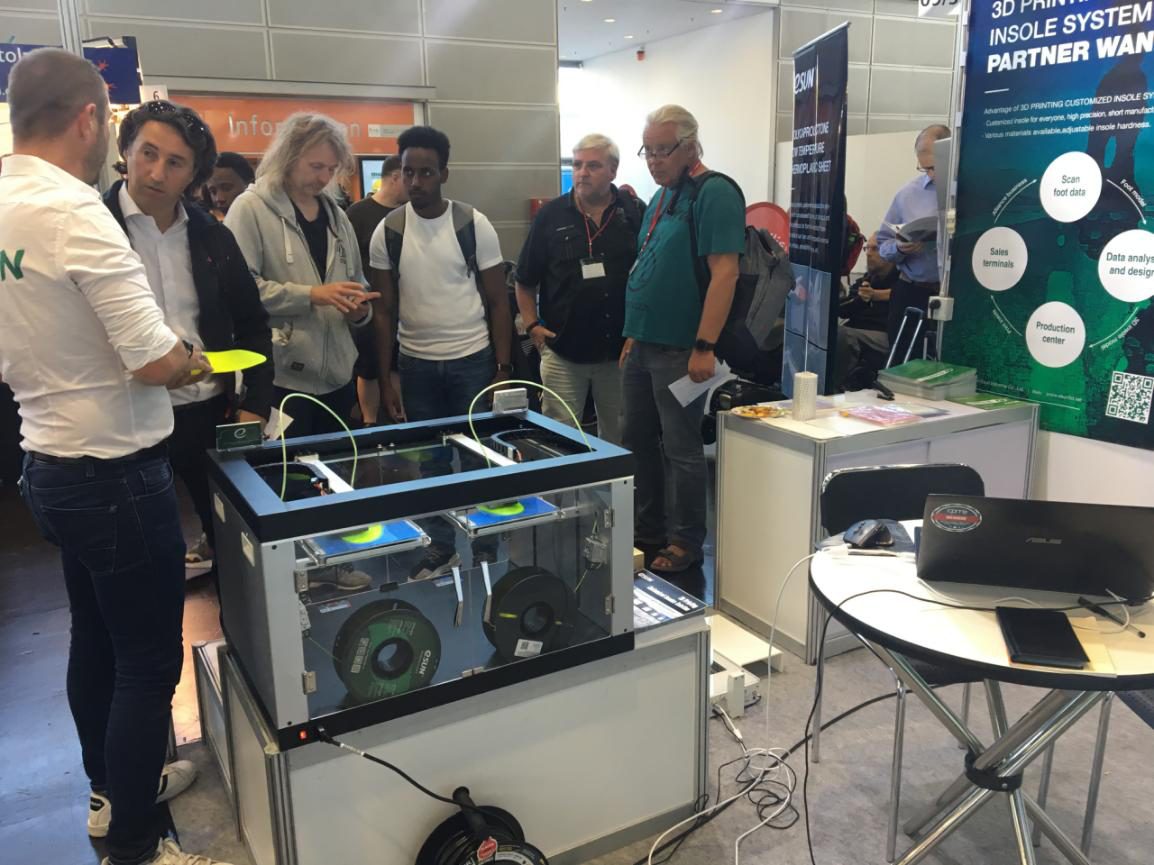

It is worth mentioning that the iSUN3D customized 3D Printing insole system attracts a large amount of traffic for the eSUN booth.

The system combines 3D scanners, 3D printers and customized insoles to help more patients with foot disease. People are deeply attracted and eager to try it.

Our distributor Mr. Jerome, who just attended the 3D PRINT in France, is more passionate about the iSUN3D customized 3D Printing insole system after learning the potential market at the last exhibition.

At REHACARE, Jerome carefully disinfecting 3D scanners, and explaining the principles and functions in detail for every customer. Jerome said that he has been busy with the iSUN3D customized 3D Printing insole system for the whole summer!

iSUN3D customized 3D Printing insole system is not only because it can completely replace the traditional insole customization. Compared with the common insole laser engraving technology, it greatly helps with the environment! First of all, it saves manpower with one-time molding and no post-processing; secondly it saves materials, with high performance and variety of choices; environmentally friendly, no noise and no dust; low cost, cost-effective and short production time!

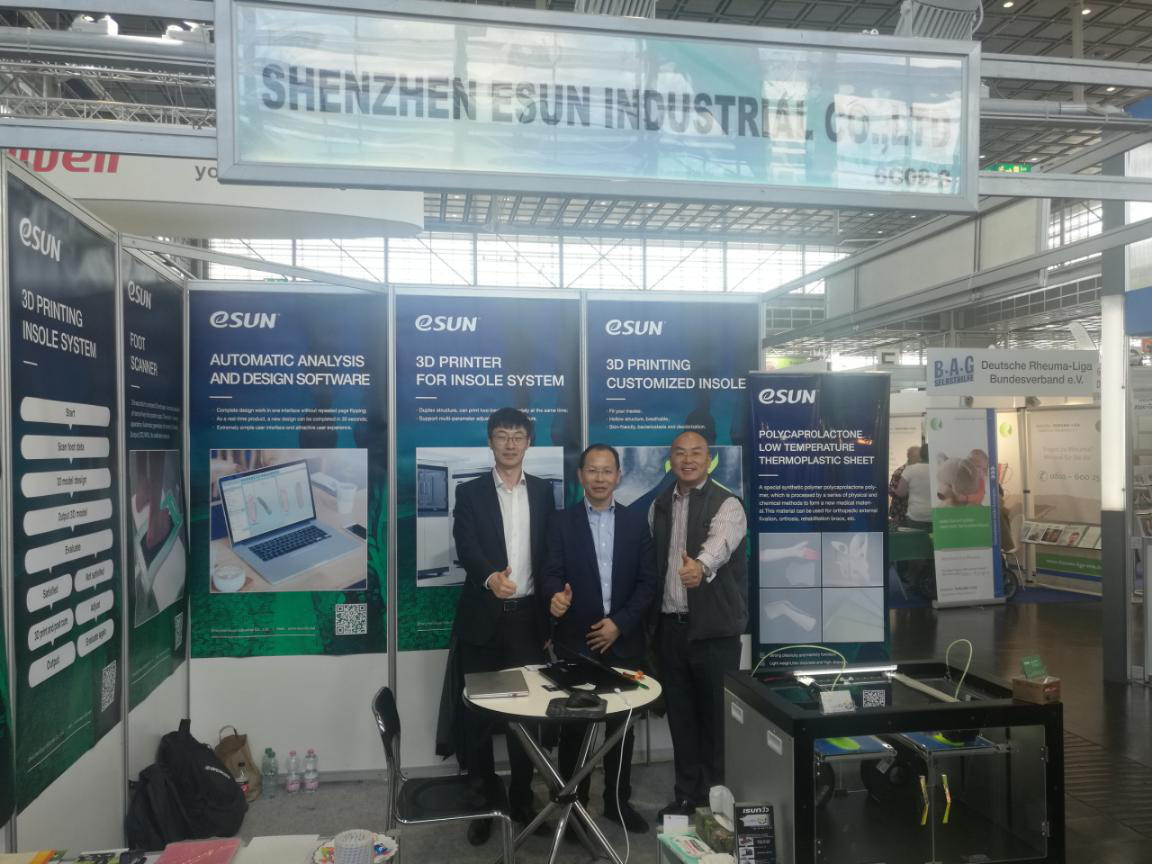

This insole printing solution, from materials to equipment and follow-up printing training, are all provided by eSUN, the buyers do not have to worry about after-sales issues. Several Italian college students consulted Jerome about it, and our friends Mr. Fang and Dr. Wu came to visit and immediately wanted to join and develop the German market together!

Italian college students and Jerome teacher are having discussion

Mr. Fang (right), Dr. Wu (left) and eSUN CEO Mr. Yang

The above is all the highlights of this exhibition, please feel free to contact us.

Phone number: +86 712 2593226(2593227)

Email: bright@brightcn.net

QQ: 2304729480

WeChat: GWWYeSUN

Or you can leave a message here, we will get in touch with you as soon as possible!