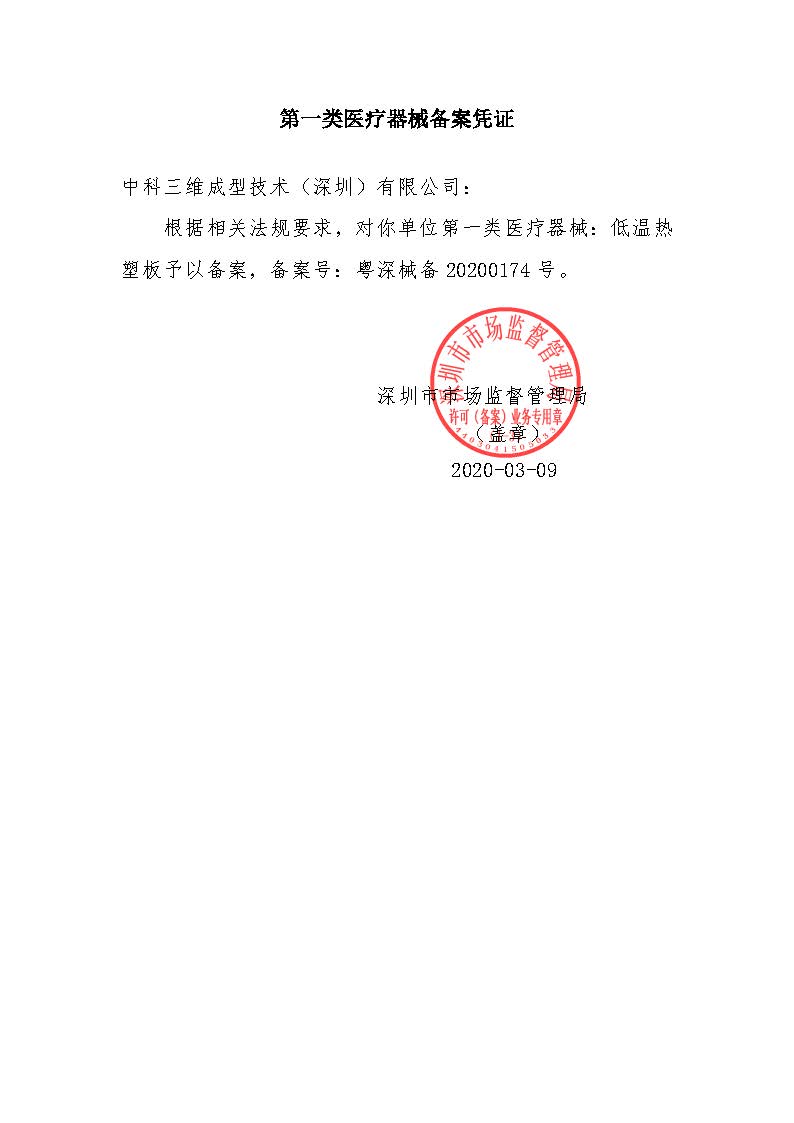

Low Temperature Thermoplastic

Product name: Low Temperature Thermoplastic

Product name(cn): 低温热塑板

Brief: Low Temperature Thermoplastic

Introduce:

OVERVIEW

Description

eSUN Low Temperature Thermoplastic

eSUN’s Materials of Polycaprolactone(PCL) advantage

Range of application

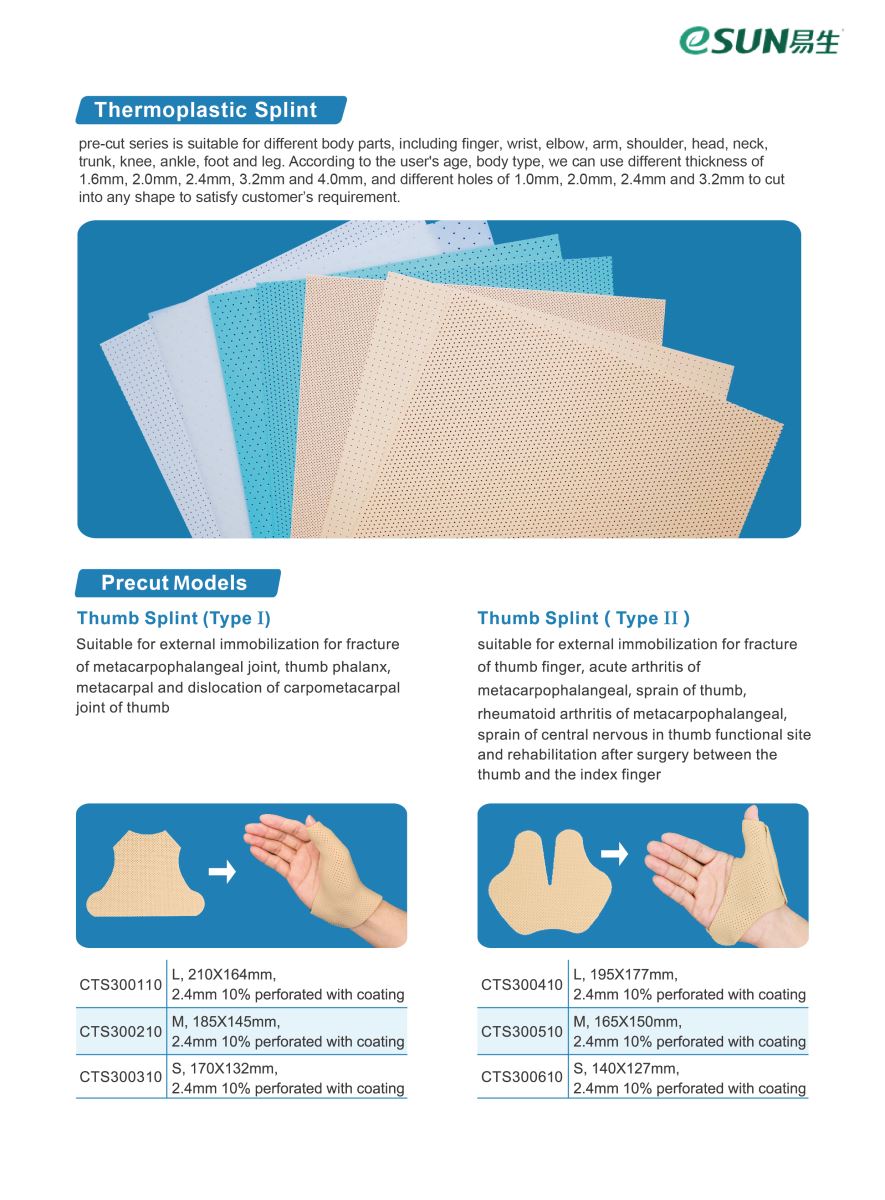

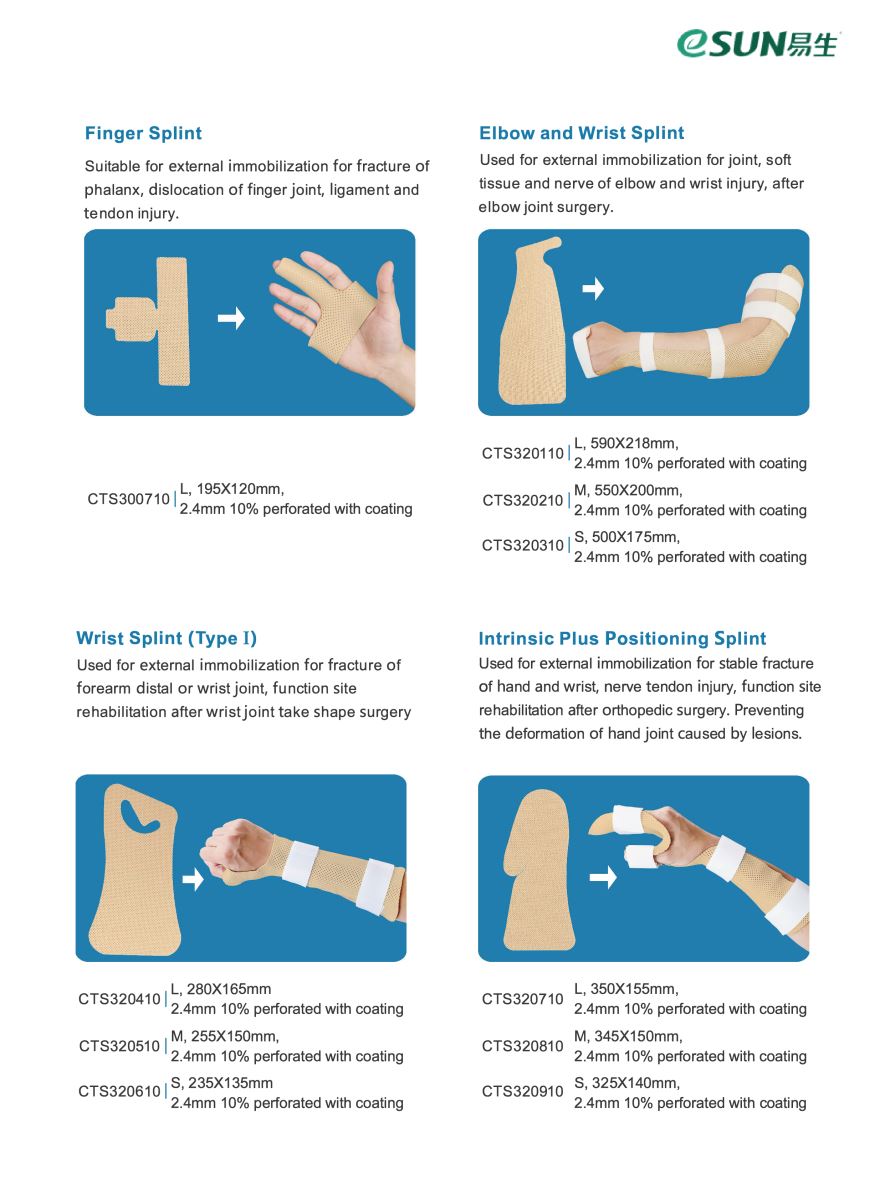

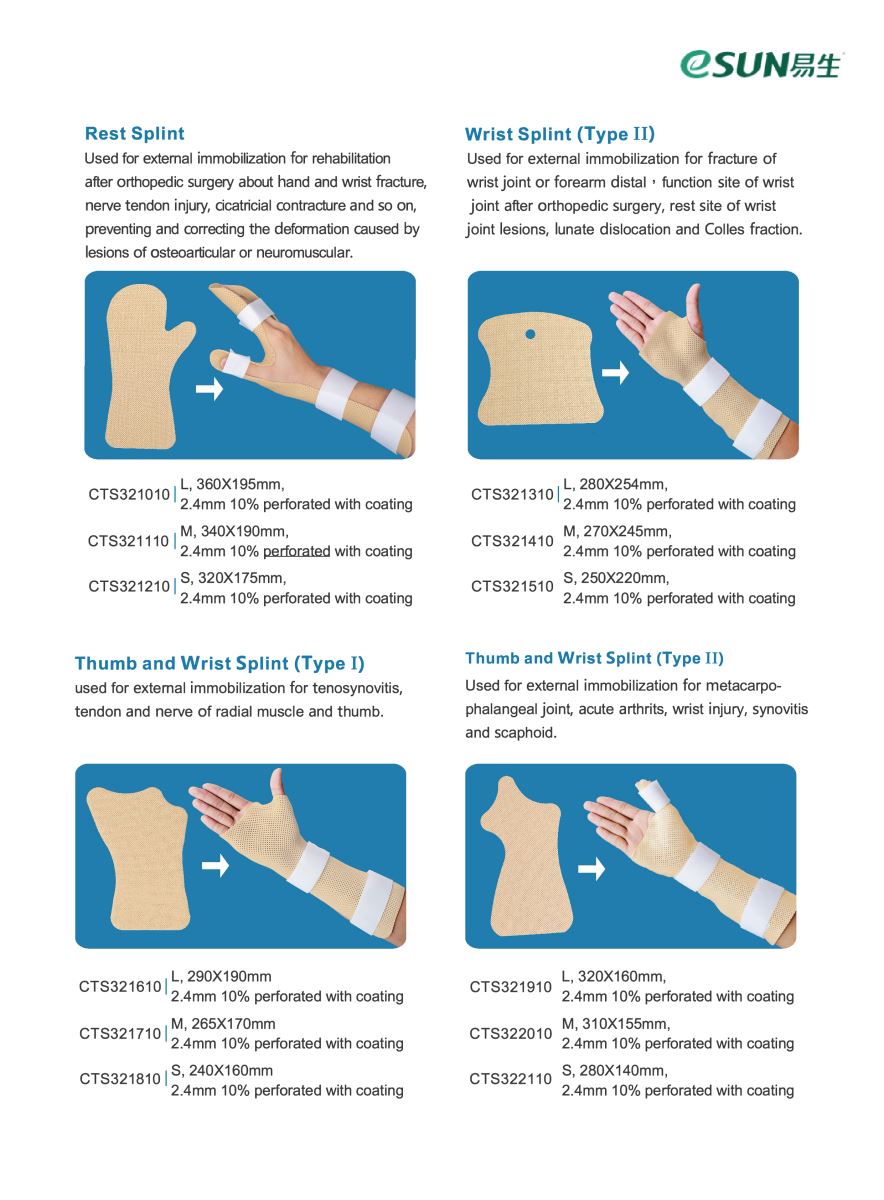

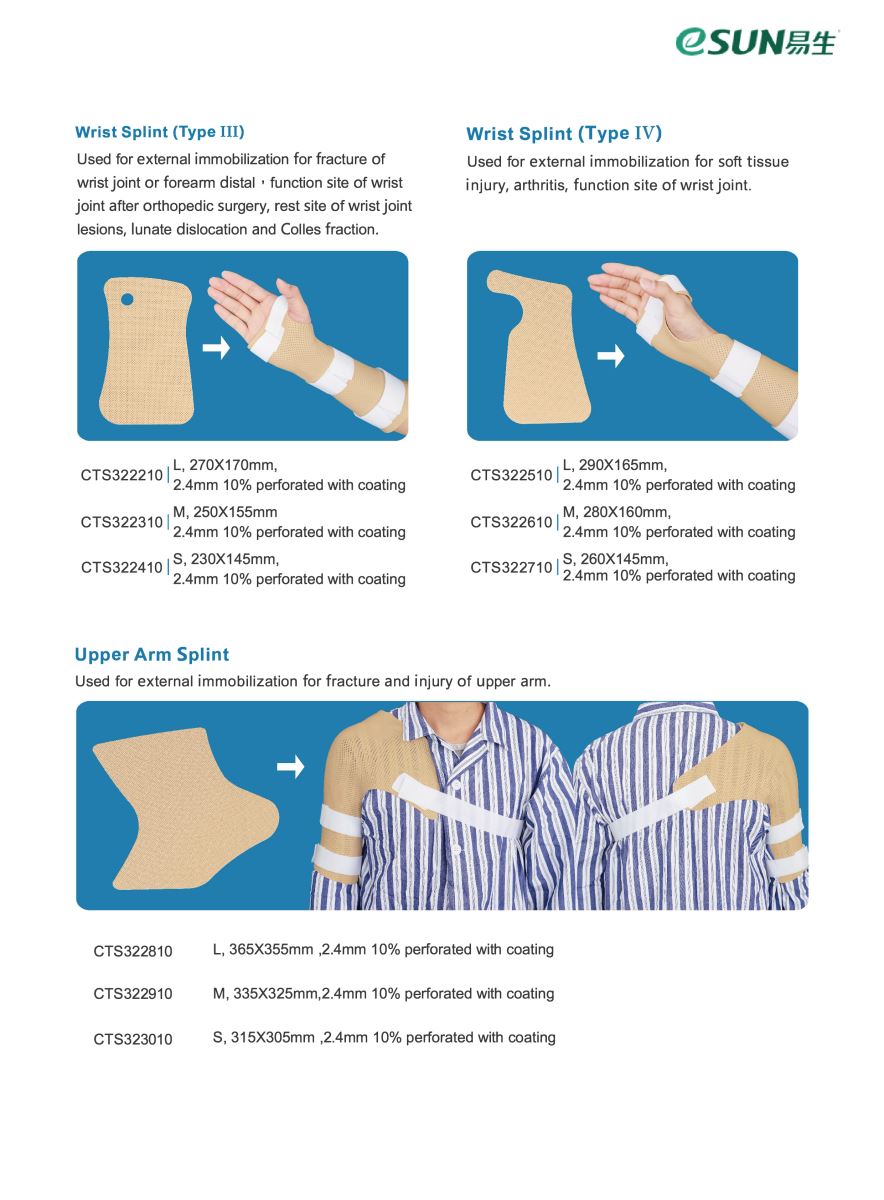

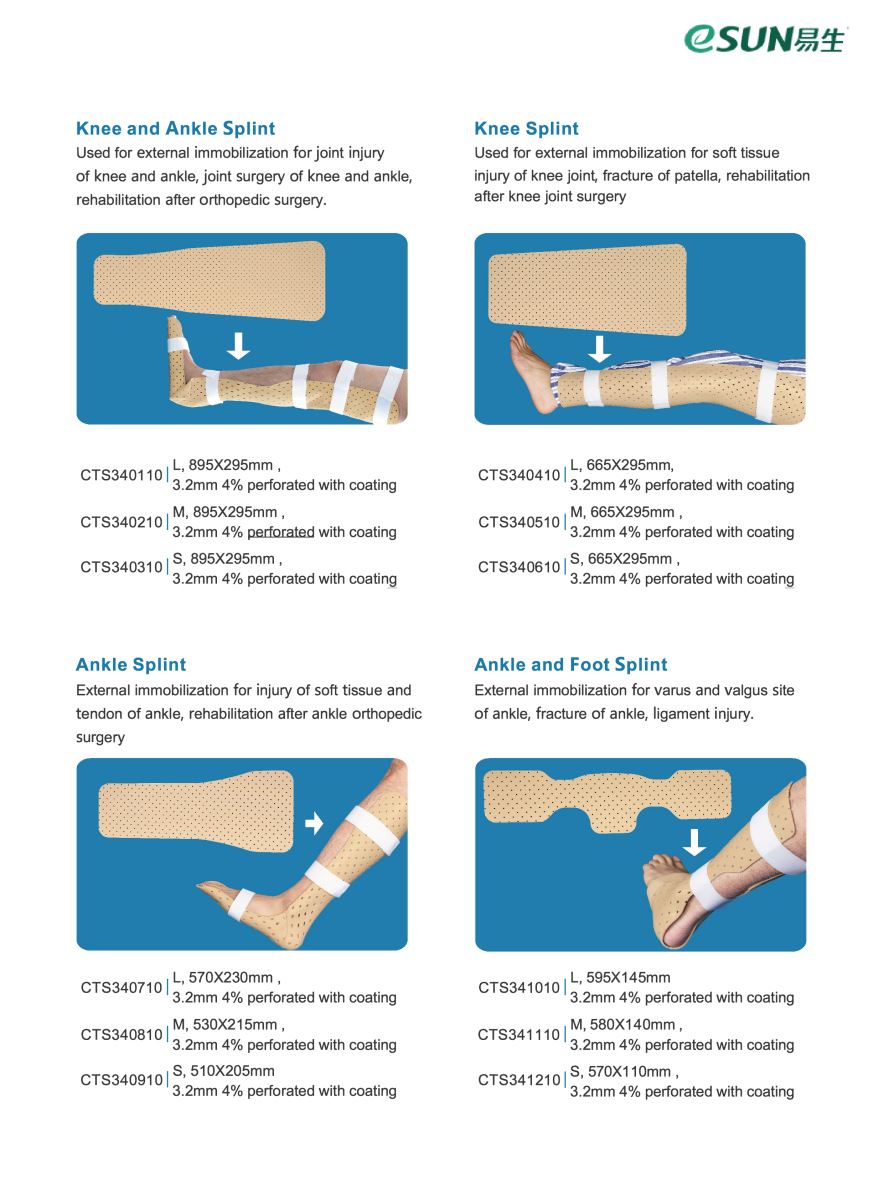

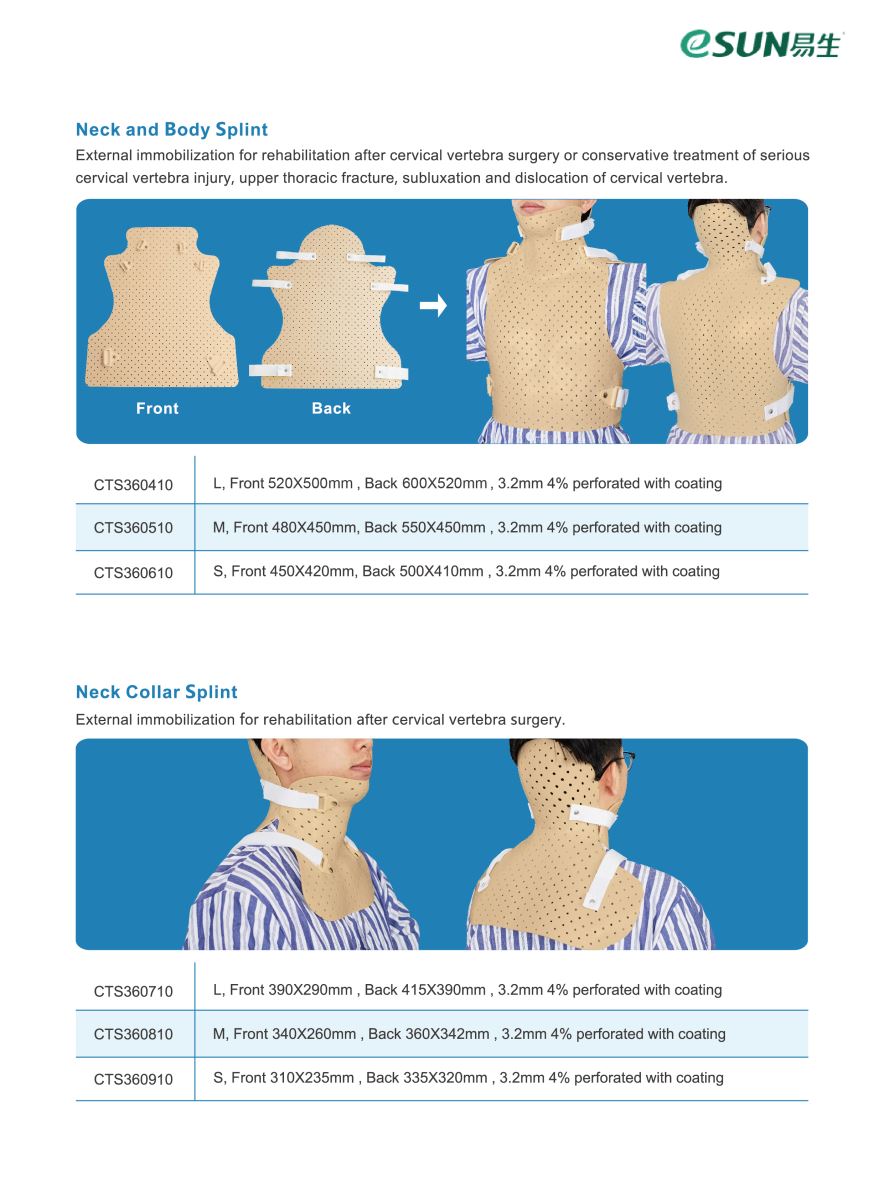

It is mainly used for Joints, Bones, Soft tissues, Nerve injuries, Burns, Plastic fixation, Rehabilitation functional braces and Orthotics making.

Notice for use

1. The low-temperature thermoplastic board belongs to a class of medical devices and cannot be used as an implanted device or in an open wound or mouth.

2. Avoid injury caused by auxiliary tools.

3. Ensure that the operation can be easily performed in a comfortable condition, and the patient can be operated in a comfortable position.

4. Ensure that the temperature will not harm to the patient when the product is shaping and fixing, it is best to wear pads on the body surface to protect the skin.

5. During the shaping process, the position of the limbs should be kept unchanged until it is cured, and the edges should be rolled outward to form smooth round edges to avoid abrasion of the patient's skin.

6. Use neutral soap and cold water to clean the product. Keep the product away from heat sources, such as open fire or microwave oven, etc. If the temperature exceeds 51℃, the product will be deformed.

7. Do not use the heat gun to shaping when the product worn on the human body.

8. Reuse carefully

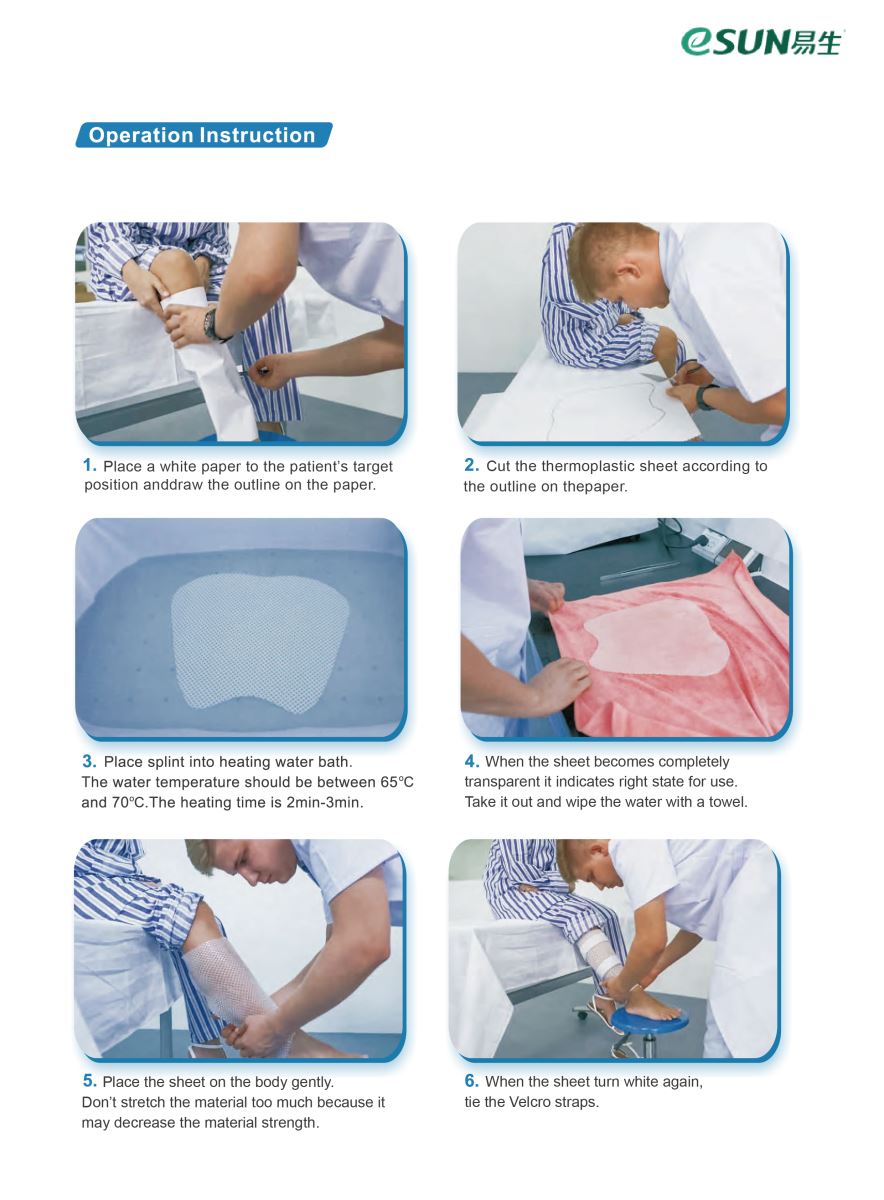

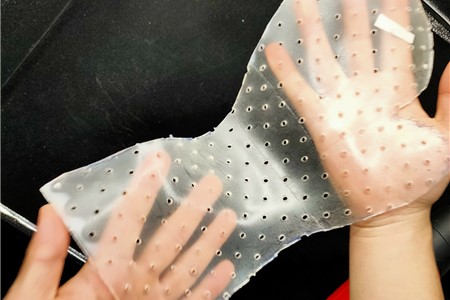

Method of application

1. Prepare materials and tools, check the water tank, and adjust the temperature of the water tank to 65-70℃.

2. Select the appropriate plate according to different conditions, measure the size of the fixed limb, design the drawing, and select the appropriate plate for cutting.

3. Doctors and patients choose appropriate posture, state the purpose clearly, and ask the patient to coordinate.

4. Put the cut plate into water at 65-70℃, heat up 1-3 minutes, and then take the softened material out of the water and wipe off the water.

5. Place the plate on the patient's fixed position and shape it. The operable time is 3-5 minutes by normal temperature in the room, the edge can be turned outward, and pay attention to the fixed angle.

6. When shaping for tube form, can use the HOOK & LOOP to fixed.

7. If the shaping is unsuccessful at the first time, it can be put into the water to shape again. If the limb edema disappears, it also can be shaped again (to avoid large-scale pulling).

8. After the sheet is hardened and formed, put it out, fix the edge part, and if necessary, soften and shape again.

9. After the molding hardened, use HOOK & LOOP to fixed then everything is done, Window treatment can be performed on the wounded area.