News & Media

New Patent! eSUN Biodegradable Hot Melt Pressure-Sensitive Adhesive

2023-09-18

Recently, the production technology of "Biodegradable Hot Melt Pressure-Sensitive Adhesive" independently developed by Shenzhen Esun Industrial Co., Ltd. and its subsidiary, Xiaogan Esun New Material Co., Ltd., has been approved by the China National Intellectual Property Office and has obtained a national invention patent authorization. ESUN has applied for nearly 100 national patents and obtained more than 60 patents, focusing on invention patents.

This patent authorization represents a further improvement in the eSUN environmentally friendly product portfolio. In the future, this patented technology will help address the existing materials used for making hot melt pressure-sensitive adhesives that cannot biodegrade under natural conditions, contributing to the development of ecological environmental protection.

I. About Hot Melt Pressure-Sensitive Adhesive

Hot melt pressure-sensitive adhesive (HMPSA) is an adhesive that primarily consists of thermoplastic elastomers. It is mixed with tackifying resins, softeners, and other additives, making it a solvent-free, non-polluting, low viscosity at high temperatures, and easy-to-use adhesive. It exhibits pressure sensitivity at room temperature. It is applied in a molten state and can be quickly bonded under mild pressure and easily removed without contaminating the adhered surface when cooled and solidified.

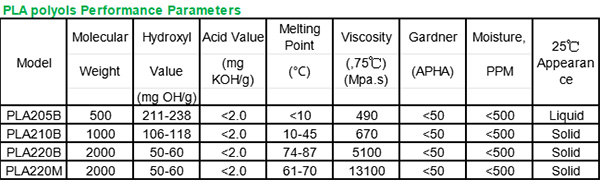

II. eSUN Polylactic Acid Polyols and the Application in Hot Melt Pressure-Sensitive Adhesives

The primary raw material for preparing eSUN's biodegradable hot melt pressure-sensitive adhesive is polylactic acid

polyol. ESUN develops polylactic acid polyols and has already achieved industrial-scale production. It is an artificially synthesized, fully biodegradable, thermoplastic aliphatic polyester polyol. The primary raw material, lactic acid, is a renewable resource. It is non-toxic, non-irritating, and exhibits excellent biocompatibility. It can biodegrade and be absorbed by biological systems, ultimately breaking down into carbon dioxide and water.

Compared to traditional alcohol-acid polyester polyols, polylactic acid polyols provide higher hardness and wear resistance to polyurethane materials while also possessing better hydrolytic stability. They are widely used in coatings, foams, elastomers, and other fields, making them an excellent raw material.

By replacing petroleum resin with biodegradable polymer polyols, eSUN's technology allows for adjusting the softening point and viscosity of the tackifying resin by controlling molecular weight and molecular structure.

III. Performance and Applications of eSUN Biodegradable Hot Melt Pressure-Sensitive Adhesive

eSUN's biodegradable hot melt pressure-sensitive adhesive exhibits excellent initial tackiness outstanding peel strength, contains no organic volatile solvents, and is biodegradable.

Based on its outstanding performance, eSUN's biodegradable hot melt adhesive can be widely used in the biodegradable packaging bags, labels, tapes, medical and sanitary products (such as band-aids), diapers, and other care products.

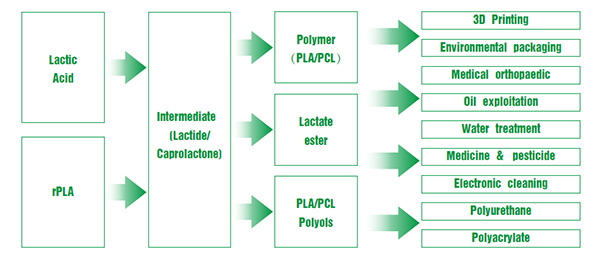

This patent authorization reflects eSUN's continued exploration and technical innovation in the direction of environmentally friendly materials industrialization. Based on the synthesis and modification of bio-materials, eSUN has applied environmentally friendly products to various fields, such as biomedical materials, 3D printing, ecological fibers, disposable degradable products, green solvents, etc. Through the innovative technology of bio-based material "X" configuration joint production, eSUN can further diversify the source of raw materials and the variety of final products in a single production line, enriching the production line's functions, effectively improving the efficiency of the production system, reducing energy consumption and costs.

“Green consumption” has become a trend, and eSUN will continue to focus on the research, development, production, application, and recycling of bio-materials and modified materials, providing efficient and comprehensive solutions for enterprises and users. eSUN is always welcoming cooperation with upstream and downstream enterprises to promote the further development of the bio-materials industry!