News & Media

Properties and application of eSUN polylactic acid copolymer PLCL

2023-07-03

Polylactic acid copolymer PLCL (copolymerized modified polylactic acid eCo-PLA) is a polymer material obtained by copolymerizing L-lactide and other monomers. Through copolymerization modification, PLCL can effectively control the melting point, transparency, toughness, and heat resistance of polylactic acid, and make up for the deficiency of blending modification.

Polylactic acid (PLA) has good biocompatibility and processing properties, but it has a slow degradation rate, brittle texture and low mechanical strength which limit the application of PLA. Polycaprolactone (PCL) has good biocompatibility, biodegradability and drug permeability, good toughness, processability and heat-induced shape memory properties, but also has low strength and hydrophilicity. Through copolymerization modification, the CL segment is introduced into PLA, which can adjust the crystallinity, biodegradability, and mechanical properties of the product, so that the material has good flexibility and elasticity, and can be widely used in biomaterials, 3D printing, and plastics. Degradable biological products and other fields.

一、Product display

二、Product Features

1. Good compatibility: PLCL has good compatibility with conventional plastics and rubber, etc., and can be used in plastic modification, adhesives (hot melt adhesives) and other related fields.

2. Good processability: its melting point is 110-130°C, it has moldability, extensibility, extrudability and spinnability.

3. Good rigidity and flexibility: It has good tensile strength and elongation at break at room temperature.

4. Shape memory: The deformed product can be restored to its original shape after heat treatment.

5. Biocompatibility: non-toxic, good compatibility with biological cells in vivo, and can be used as a drug-controlled release carrier in vitro.

6. Biodegradability: In the soil microbial environment, it can be completely decomposed into CO₂ and H₂O, which is an excellent biodegradable polymer.

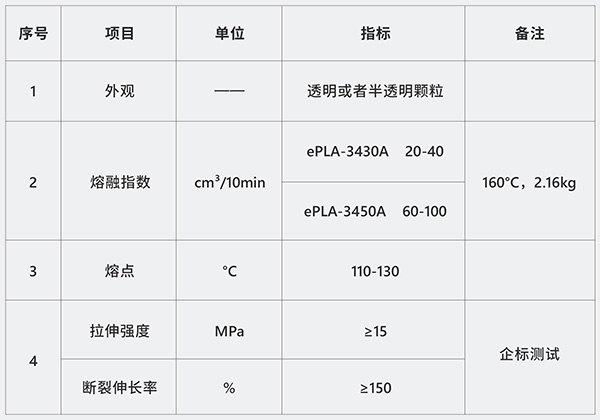

三、 Product physical index

四、Product application

1. Adhesive

Polylactic acid copolymer eCo-PLA can be used as a matrix resin for hot melt adhesives, and the prepared adhesive is suitable for applications with short open times, such as bonding of all high-end leather shoes, riding boots, women's shoes, children's shoes, work shoes and various sports shoes. It can also be used as a compatibilizer, plasticizer, etc.

Application advantages:

① Low melting point, easy construction, good permeability to substrate;

② Good adhesion to leather and oily substrates;

③ Polar polyester, easy to color or dye;

④ Good compatibility with various polymers;

⑤ Excellent hydrolytic stability;

⑥ Folding and pressure resistance, green and environmental protection, biodegradable.

2. Film

The elongation at break of PLCL is ≥150%, and the toughness is good. It can be prepared by various methods such as extrusion, blow molding, calendering, casting and stretching. The overall performance is similar to that of traditional PE and PBAT blown film materials. , film transparency is good.

Advantage:

① Low melting point, easy to process;

② High elongation and tensile strength;

③ Environmentally friendly and biodegradable.

3. Textile industry

It can be used as a functional coating and functional finishing of fabrics, such as clothing interlining (cuffs, necklines, etc.), so that it has good anti-wrinkle and wear-resistant properties, and can be recovered by raising the temperature.

Advantages: Sensitive to temperature, has good shape memory function.