News & Media

eSUN carbon fiber reinforced nylon [ePAHT-CF] is coming soon!

2020-07-22

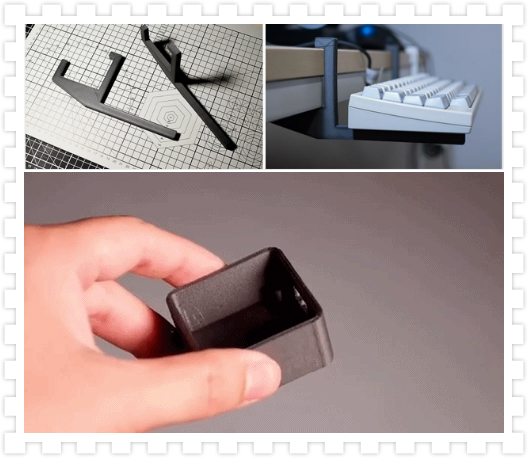

For makers, filament with a certain degree of impact resistance, density and toughness is required. For example, printing saddles for racing horses and race bike seat, nylon materials are the best choice.

This is not only because of the light density, but also its rigidity, hardness and other characteristics of nylon that make the parts not easy to deform and fade, and it is strong and durable. Through the miniaturization of automobiles, the efficiency of electronic and electrical equipment, and the lightweight of mechanical equipment, industrial fields have higher requirements and greater demands for nylon materials.

eSUN ePA-CF print

Market demand urges nylon as a structural material and improves its strength, heat resistance, and cold resistance.

◐ As early as 2015, eSUN produced the first ePA nylon filament, with high flame retardancy as the biggest feature;

◐ Then in 2017, eSUN used nylon as the base material to produce ePA-CF carbon fiber reinforced nylon by adding carbon fiber materials to increase the strength of the material, while also reducing the weight of the product and maintaining the original abrasion resistance, chemical resistance, weather resistance and other characteristics, it is still selling well since its launch.

ePAHT-CF nylon carbon fiber launched this time is actually an upgraded version of ePA-CF, which was jointly developed by eSUN and LUVOCOM. The characteristics of this product have a more professional use of the characteristics of nylon materials, its toughness, rigidity, high-temperature resistance, modulus and other performance indexes are higher than conventional nylon filament.

ePAHT-CF Carbon Fiber Reinforced Nylon, using Lehvoss LUVOCOM 3F series 9742 BK material, which adds 15% high-rigidity carbon fiber to the nylon 6 base material, so that the material has higher modulus, mechanical strength and rigidity, the continuous use temperature can be up to 150 ℃, the strength and toughness has also been further improved, greatly improving warping problem even for larger size prints. The shrinkage and water absorption are also greatly reduced, printing accuracy is high, and the product is more wear-resistant.

Certification by Lehvoss

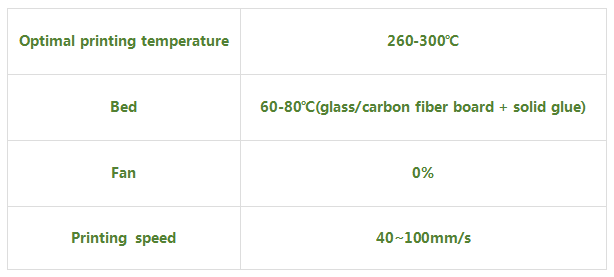

ePAHT-CF printing parameters

Note: ePAHT-CF are easy to absorb water, so please dry before printing (70℃/12H). It is recommended to use with the eBOX when printing. In addition, ePA6-CF is also easy to grind nozzles and extruder gears. It is recommended to use hardened steel nozzles or ruby nozzles. Hardened steel extruder gears can be selected if possible. If the printing time of the throat is long, it needs to be replaced.

ePAHT-CF carbon fiber reinforced nylon application areas:

1. Automobile industry, due to the excellent oil resistance, wear resistance and creep resistance of ePA6-CF, it can replace traditional metal materials and has the advantage of light weight, such as the manufacture of engine parts, electrical parts and car body parts; It is excellent fatigue resistance can be used in the manufacture of synchronous drive gears for automobile internal combustion engines;

2. National defense industry, which can replace metal materials, mainly used in the fields of national defense and aerospace, such as the manufacture of missile engine parts, rocket launchers, rocket tails, etc.;

3. Aerospace, since the material itself is lighter than traditional aluminum, it is extremely beneficial to increase manufacturing speed and save fuel;

4. Stationery and sports goods, which can be used to manufacture thin-walled products, such as helmets, automobile bumpers and robot arms.

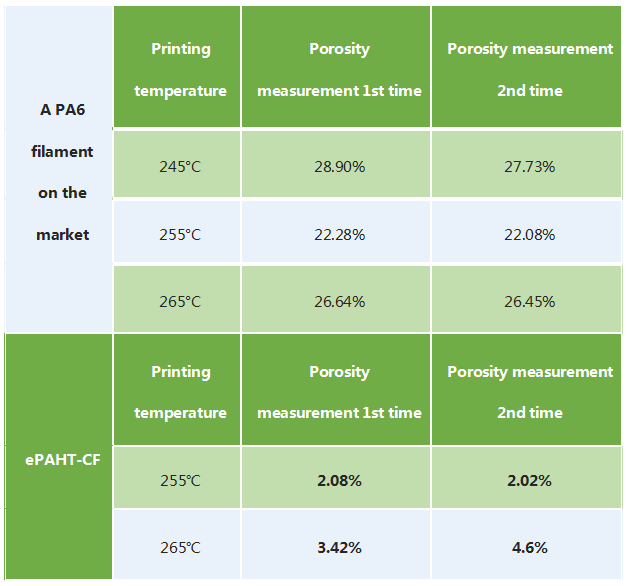

We sampled some PA6 and eSUN ePAHT-CF filament on the market, and performed various performance tests and comparisons under the same conditions.

Micro-CT analysis of a PA6 filament on the market

Micro-CT analysis of ePAHT-CF filament

Under the same conditions and the same temperature, the micro-CT analysis concluded that the porosity data of ePA6-CF is much smaller. Compared with a PA6 filament on the market, ePAHT-CF has better printing accuracy and better wear resistance.

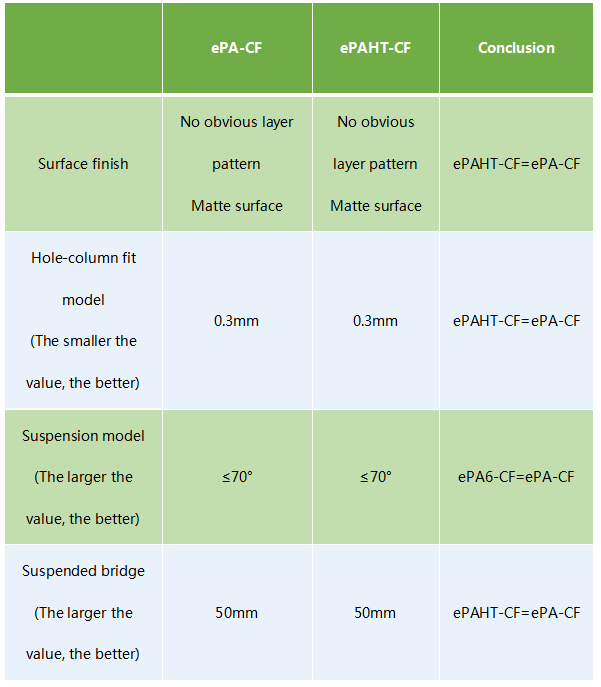

Later, we evaluated ePAHT-CF and ePA-CF of eSUN, and compared the printing performance of the two materials. The specific data conclusions are as follows.

Performance comparison between ePAHT-CF and ePA-CF

Note: Print test conditions: nozzle 280℃; bottom plate 80℃; speed 40mm/s

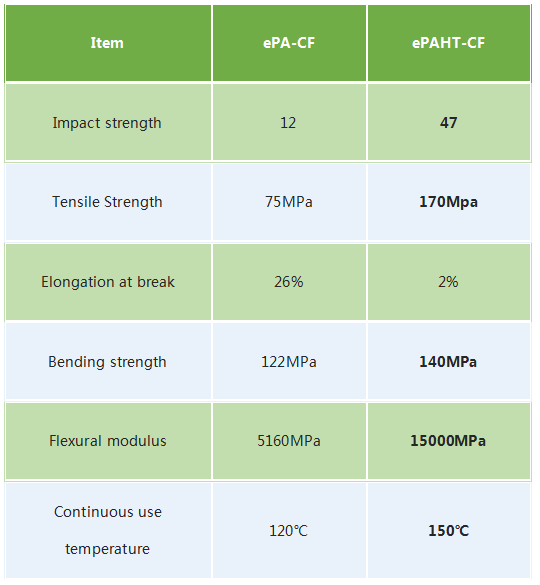

ePAHT-CF VS ePA-CF physical properties:

In summary, ePAHT-CF, as a new filament of eSUN nylon series, has higher impact resistance, greater tensile and flexural strength; the flexural modulus is significantly improved, which is nearly three times that of ePA-CF ; Strong toughness, heat resistance up to 150 ℃, very suitable for objects with high performance, high temperature resistance and special properties.

Following the launch of super-tough PLA [ePLA-ST], [ePAHF-CF nylon carbon fiber] will be launched immediately. Feel free to contact us for a trial and explore the new world of 3D printing together!

Contact number: 0755 86581960

Email: bright@brightcn.net

WeChat: GWWYeSUN

Or leave a message at the end of the article, we will get in touch with you as soon as possible!