News & Media

Shenzhen Esun Industrial Co., Ltd. has officially completed the acquisition of controlling interest in HI-TECH CHANGJIANG PLA CO.,LTD.

2023-12-29

In December 2023, Shenzhen Esun Industrial Co., Ltd. completed the acquisition of a controlling interest in HI-TECH CHANGJIANG PLA CO., LTD. (hereinafter referred to as Hi-Tech Changjiang). With the completion of the business registration change, Hi-Tech Changjiang officially became a subsidiary under the control of eSUN.

About Hi-Tech Changjiang

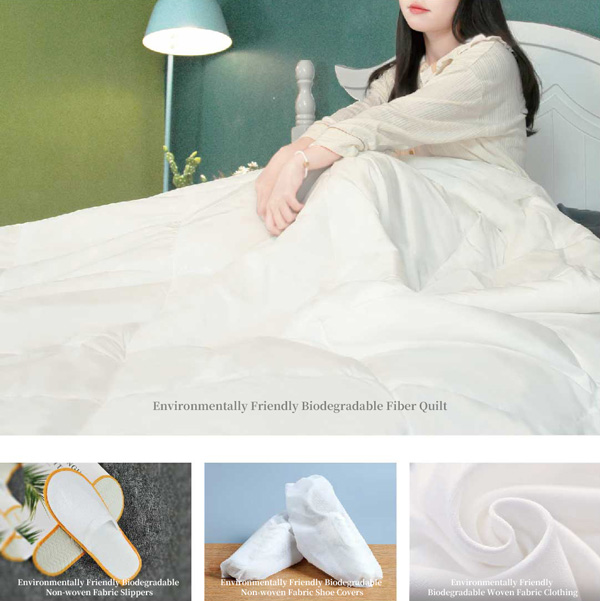

Hi-Tech Changjiang was established in 2000, and since 2006, the company has been involved in the research and production of polylactic acid fiber and related products. In 2015, it became a part of Hi-Tech Fiber Group Corporation, specializing as a supplier of polylactic acid fiber and non-woven fabrics.

The company has extensive experience in researching, producing, and applying products such as PLA yarn, PLA staple, and PLA non-woven fabric. Among them, the "Continuous Polymerization Melt Direct Spinning Polylactic Acid Fiber", pioneered globally by Hi-Tech Changjiang, was recognized by the Ministry of Science and Technology as a "National Key New Product." The "Polylactic Acid Efficient Biosynthesis and Fiber Preparation and Application Technology" project, completed with the participation of Hi-Tech Fiber Group Corporation and Hi-Tech Changjiang, also received the first prize in the 2023 China Textile Industry Federation Science and Technology Progress Award.

Awarded the 2017 National Key Research and Development Program

Received the First Prize in the 2023 China Textile Industry Federation Science and Technology Progress Award

The "Polylactic Acid Efficient Biosynthesis and Fiber Preparation and Application Technology" project achieved a significant breakthrough in overcoming the bottleneck of high-quality large-scale manufacturing of PLA fibers. This was accomplished by applying high-purity, low-cost lactic acid production technology, propylene glycol, and PLA fiber processing technology. Additionally, the project successfully reduced production costs by developing continuous polymerization-melt direct spinning polylactic acid fiber processes and related equipment.

Regarding production capacity, Hi-Tech Changjiang had previously completed the construction of the first production line for continuous polymerization-melt direct spinning dual-component PLA fibers with a capacity of tens of thousands of tons. Additionally, they established a production line for PLA staple fiber non-woven fabric with a capacity of thousands of tons. This achievement marked the world's first industrialized polylactic acid thermal-bonded non-woven fabric production line.

Advantageous Integration and Strong Collaboration

As early as 2006, eSUN began exploring the field of polylactic acid fiber and its applications. In 2021, eSUN and Hi-Tech Changjiang signed a strategic cooperation agreement to jointly expand the processing and application of polylactic acid fiber, making significant progress. The controlling acquisition of Hi-Tech Changjiang by eSUN represents not only a strong collaboration between two pioneers in the field of biomaterials but also an advantageous integration of a company dedicated to polylactic acid synthesis and fiber applications for 15 years with another specializing in polylactic acid synthesis modification and applications for 20 years.

Perfecting the Four Major Application Layouts, Establishing a Green Closed-Loop Industrial Chain

Guided by the principles of "Differentiated Positioning, Open Innovation. " eSUN is committed to synthesizing, modifying, applying, and recycling biomaterials. With over two decades of development, we have successfully established a green closed-loop development system. This system focuses on perfecting four major application layouts to create a comprehensive and sustainable industrial chain in bio-materials.

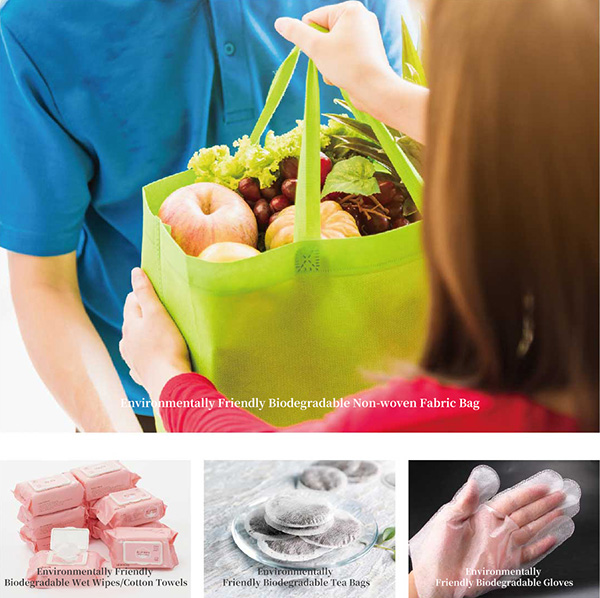

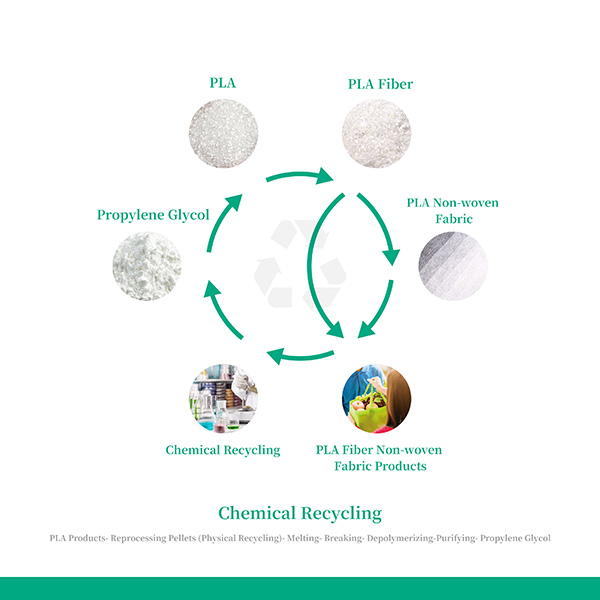

Through this acquisition, ESUN will address the production capacity gap in polylactic acid fiber. Focusing on the research and application of biomaterials, we are taking steps to establish a preliminary application layout in four areas: "biomedical applications, 3D printing, ecological fibers, and biodegradable products." Furthermore, it aims to create a green closed-loop industrial chain by integrating polylactic acid chemical recycling, propylene glycol recovery, and melt direct spinning to produce polylactic acid fibers.

Since 2006, eSUN has been actively involved in research on the recycling and high-value reuse of polylactic acid. In 2012, we formally submitted a patent application for the method of "Recycling Polylactic Acid to Produce Refined Grade Propylene Glycol" and successfully obtained the invention patent in 2014. In 2013, eSUN completed the construction of a chemical recycling production line for propylene glycol with an annual capacity of 5,000 tons at its factory in Xiaogan, Hubei.

In the first half of 2018, Hi-Tech Changjiang completed the construction of the world's first production line, capable of annually producing ten thousand tons of polylactic acid synthesized from propylene glycol and direct spinning polylactic acid fibers. This production line utilized their proprietary "Polylactic Acid Melt Direct Spinning" technology, eliminating the need for slicing, resulting in a 30% reduction in energy costs and an overall savings of 2100 yuan per ton. The combination of patents and production lines from both companies is poised to make chemical recycling of polylactic acid and the melt-direct spinning of fibers a practical reality.

Completing the Domestic Industrial Regional Layout

Based on assessments of domestic and international comparative advantages, eSUN has been actively constructing a development layout encompassing both domestic and global cycles. Internationally, leveraging the demographic dividend in Southeast Asia, we have established a manufacturing base in Vietnam and positioned itself strategically in the "front store, rear warehouse" layout in Europe and America. Domestically, by capitalizing on the engineering talent dividend, eSUN has increased research and development investment and focused on technological innovation. With the integration of Hi-Tech Changjiang into the eSUN system, we have formed a regional layout in China. In the central region, Wuhan is the research and marketing center. Xiaogan, Hubei, is the engineering, 3D printing, and biomaterial production center. In the southern part, Shenzhen is the R&D center for medical materials and the e-commerce operation center. In the eastern region, Changshu is the production center for polylactic acid fibers. This structure has created a comprehensive production, marketing, and operational pattern covering China's eastern, central, and southern regions.

Moving Forward Together, Setting Sail for Vast Horizons

Polylactic acid fiber is derived 100% from plant resources, making it biodegradable and bio-based. It possesses characteristics such as health and safety, antibacterial and skin-friendly properties, moisture absorption and sweat-wicking abilities, mold resistance and freshness preservation, breathability, moisture permeability, and resistance to UV radiation and flame retardancy. With these features, polylactic acid fiber holds excellent potential for widespread applications in various fields, including textile and apparel, medical materials, and tobacco-related products. Working hand in hand, the companies aim to explore new frontiers and contribute to advancing and adopting sustainable and innovative solutions.

In the "Implementation Plan for the Quality Improvement of the Textile Industry (2023-2025)" jointly issued by the Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Commerce, and the State Administration for Market Regulation, various bio-based fiber new materials such as polylactic acid fiber, Lyocell fiber, and bio-based polyamide fiber are identified as key breakthrough directions. The development of bio-based materials, along with the promotion of research and application of polylactic acid fiber, is expected to contribute to the green development of the textile industry, mitigate pollution, reduce energy consumption, and achieve the goals of "peak carbon emissions" and "carbon neutrality."

Hi-Tech Changjiang's integration into eSUN represents a successful practice of optimizing and consolidating industrial resources. Both parties will combine resources, complement each other's strengths, collaborate sincerely, and continue to focus on the research, application, and promotion of biomaterials. We aim to drive polylactic acid fiber's application and industrial development comprehensively. eSUN will support Hi-Tech Changjiang in technical research and development, market expansion, operational management, and funding. Together, we will work towards advancing the development of polylactic acid fiber and our application business, positioning it as the second central growth area for eSUN following the 3D printing business.

In the future, we will continue to adhere to the business philosophy of " Differentiated Positioning, Open Innovation. " We will be driven by technological innovation, focusing deeply on applying and recycling biomaterials and seizing the development opportunities brought by the "dual-carbon" initiatives.