News & Media

Applications | The Present and Future of 3D Printing Glasses

2023-12-13

In the glasses market, costs incurred due to products not chosen by consumers for reasons such as style, color, material, or other factors are typically “amortized” by increasing the selling price of the product. For glasses retailers, traditional challenges include the capital costs of bulk production and expenses related to stocking inventory in stores and warehouses. Additionally, consumers may experience issues during glasses use, such as concerns about frames being too heavy and causing fatigue over time, liking the style but finding the size unsuitable, or discomfort with nose pads and the vulnerability of frames to damage. The lack of precise customization in glass production also challenges the industry.

With the development of the 3D printing industry, 3D printing as a new manufacturing method profoundly impacts social production and life. In the glasses industry, 3D printing technology reduces common inventory risks, improves the supply chain, and enables on-demand production. Additionally, 3D printing technology contributes to shorter product development cycles and facilitates product innovation. For users, this means they can access more personalized and stylish products, offering higher comfort levels. Moreover, they have a wider range of choices in terms of materials and performance.

Approximately 15 years ago, 3D printing glasses began emerging in the market. Currently, the 3D printing glasses industry is demonstrating significant growth potential. According to data from additive manufacturing research, the market value of 3D printing glass frames has experienced remarkable growth, starting at $25.8 million in 2019. It is projected to reach an estimated $23.5047 billion by 2031. This indicates a substantial demand for 3D printing glass frames and suggests a rapid adoption of the technology in the market.

At the Formnext in Germany, which concluded in November, eSUN showcased a variety of 3D printing glasses. It garnered significant appreciation from the vast audience as a standard consumer product.

These glasses are designed by 3D Dynamics Global (hereinafter called 3DD). 3DD also provides the relevant accessories. Users can quickly 3D print and assemble the glasses using the official STL models provided, allowing them to own a pair of 3D printing glasses.

Using FDM printing technology for glass production has several advantages. On the one hand, it offers a low-cost solution that is easy to operate and enables rapid printing. Based on actual experiences, it takes only 40 minutes to print a complete glass frame, making this approach suitable for rapid prototyping. Additionally, the diverse range of 3D printing filaments provides ample possibilities for glass design, offering significant product appearance and performance flexibility.

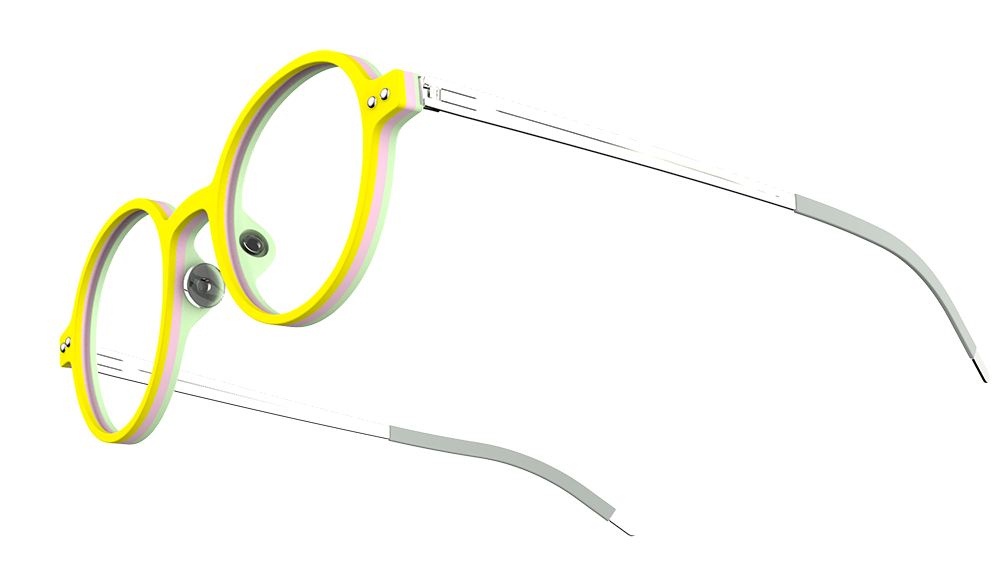

Based on FDM printing technology, 3DD introduced a brand of glasses named Macaron. The inspiration for this brand is derived from the rich color spectrum of FDM printing. 3D printing frames can exhibit diverse visual effects through color mixing or layering. The emerging multi-color printing technology continues to support the creative design and realization of 3D printing glasses.

Introduction to eSUN PLA+ Filament:

eSUN PLA+ filament is a well-balanced printing filament with superior strength, rigidity, and toughness. It exhibits strong impact resistance, making it highly suitable for printing functional parts as well as for early concept models and rapid prototyping. The well-rounded performance of this filament makes it an ideal choice for a wide range of applications in various fields.

In addition to FDM printing technology, other techniques, such as photopolymerization printing, can also be used to produce glasses, with significant development prospects. In August of this year, glasses designed by French designer @marierohanaa using eSUN's Hard-Tough Resin, sponsored by eSUN's Empower Your Dream ambassador program, appeared on stage with Beyoncé during a concert.

Regarding the development of the 3D printing glasses industry, we have also had detailed discussions with the person in charge at 3DD. Thomas mentioned, "The traditional production of glasses, from design to prototype, and until the final production, involves a certain time frame. However, by leveraging 3D printing technology, both individual designers and glasses brands can break free from traditional production processes, creating product prototypes or finished glasses at a faster pace and lower cost. Furthermore, the advantages of 3D printing in mass customization are evident, without being constrained by the time, MOQ (Minimum Order Quantity), costs, and various restrictions imposed by traditional production methods. It eliminates the need for large inventories, making 'on-demand production' a reality."

Furthermore, the ongoing revolution in high-speed printing provides favorable conditions for further popularizing 3D printing technology in industrial production and related fields.

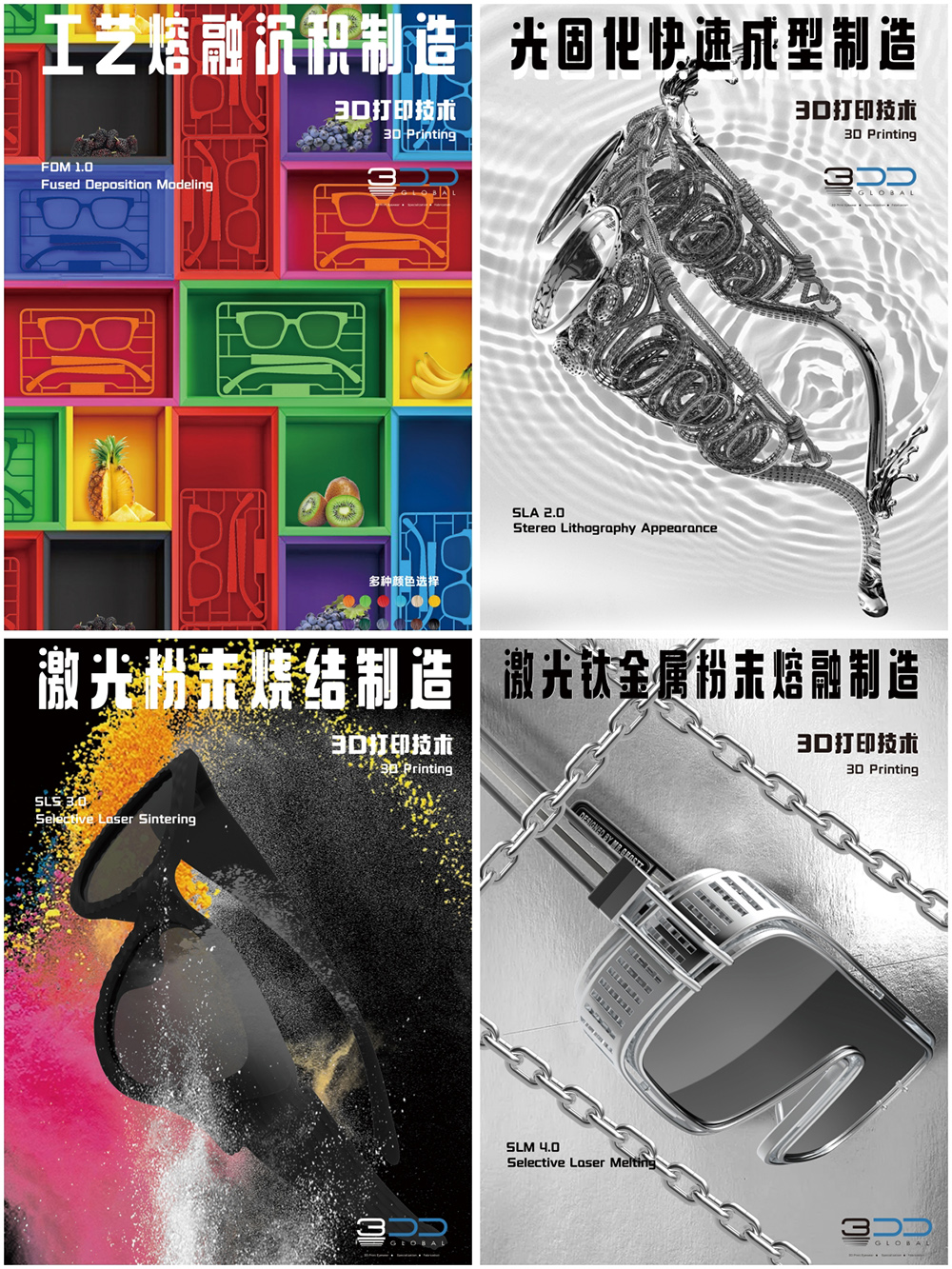

Of course, in addition to the 1.0 solution based on FDM printing technology, 3DD offers various segmented solutions in the 3D printing glasses industry, including photopolymerization printing, nylon printing, metal printing, etc. Leveraging over 30 years of rich experience in developing, producing, and selling glasses products, 3DD can turn numerous conceptual designs into reality using 3D printing technology.

The solutions from 1.0 to 4.0 each have distinct advantages, but overall, 3D printing glasses hold significant benefits in product design, production and supply chain efficiency, environmental impact, and customization opportunities.

Concerning product design, 3D printing glasses optimize comprehensive performance, such as comfort and wear resistance through material selection. Additionally, the technology provides a high degree of design freedom, significantly increasing the possibilities for creative realization. Regarding production and supply chain, 3D printing facilitates on-demand production, reducing inventory. Moreover, it transforms the entire supply chain, offering a comprehensive solution that provides more efficient and flexible services for manufacturers and individual users. As for environmental protection, 3D printing helps reduce resource waste and dust pollution in production. Additionally, it extends product lifecycles by printing replacement parts, further minimizing resource waste. Finally, the unparalleled advantage of 3D printing in customization allows for glasses tailored to individual facial features and preferences, enhancing the user experience.

With the further development and widespread adoption of 3D printing technology, the 3D printing glasses industry holds significant growth potential. As part of the industry chain, eSUN will continue to monitor and increase product research and development efforts closely. This is to provide high-quality material support for the deepening application of 3D printing technology in other industries or fields.

3D Dynamics Global (abbreviated as 3DD) is an international technology company with comprehensive 3D printing capabilities and a global strategy. The company has made significant strides in the field of 3D printing glasses. 3DD is among the few global technology enterprises that can flexibly utilize and interchange four prevailing 3D printing methods (1.0 FDM, 2.0 SLA, 3.0 SLS, and 4.0 Metal) for glass production. Furthermore, 3DD continually advances its technology from 1.0 to 4.0, actively pursuing innovation and progress.

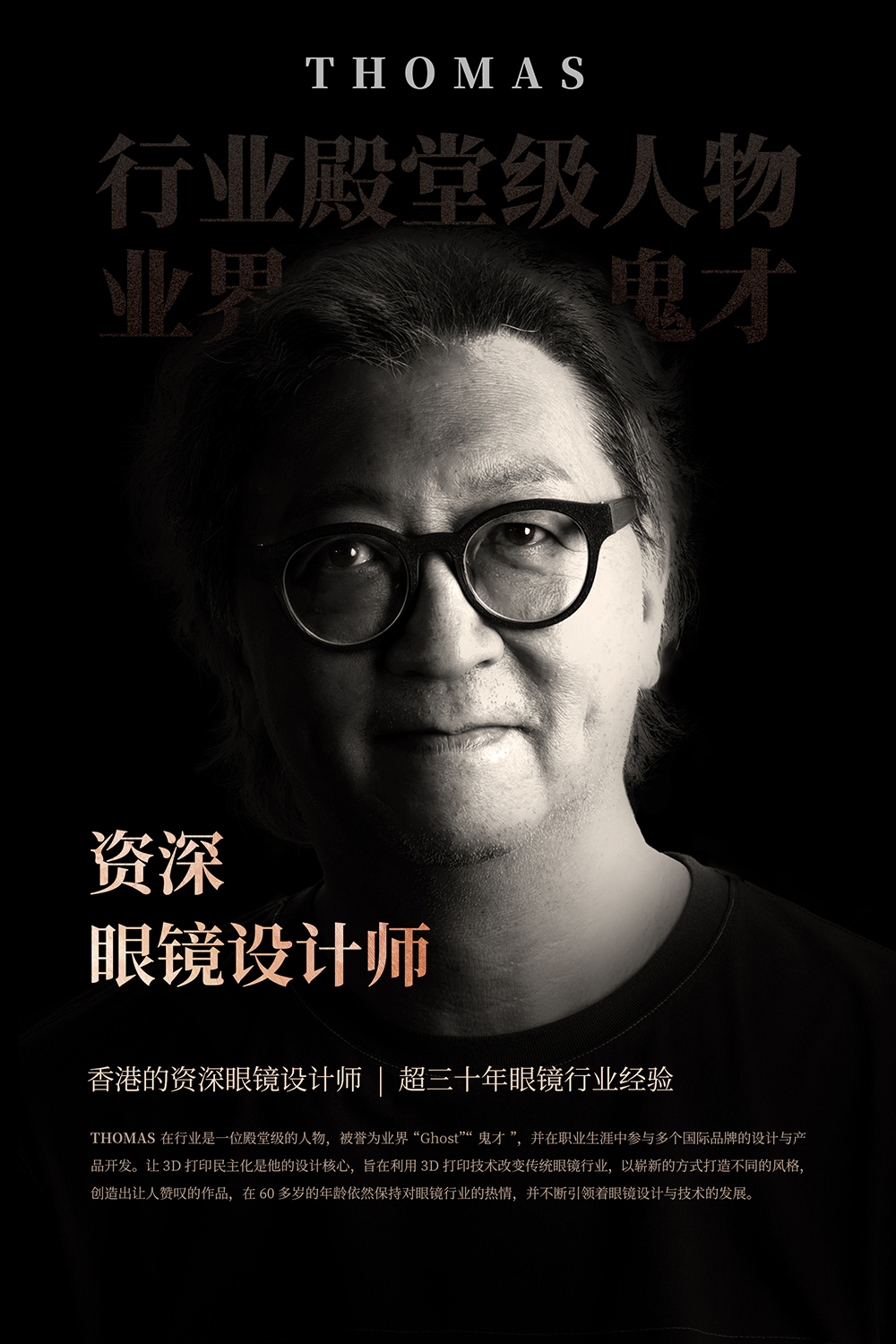

The company's founder, THOMAS, is a seasoned glasses designer from Hong Kong with over 30 years of experience in the glasses industry. He has been involved in the design and product development of several international brands. As a prominent figure in the industry, THOMAS is renowned as a "Ghost" and is considered a visionary. "Democratizing 3D Printing" is at the core of his design philosophy, and he aspires to use 3D printing technology to transform the traditional glasses industry, creating distinct styles in a novel way and producing awe-inspiring works. Despite being in his sixties, THOMAS maintains a passion for the glasses industry, consistently leading the development of glasses design and technology.