News & Media

CHINA RESTAURANT EXPO, eSUN promotes the application of environmental protection packaging products in catering industry!

2021-05-19

Historically, in our participation in a number of exhibitions, the most appetising and unforgettable is the food and beverage exhibition! A dazzling array of food and service solutions is impressive.

May 21-23, CRE will be held at the Guangzhou International Convention and Exhibition Center in Guangzhou. The expo is one of the largest, most influential and highest quality hotel and catering trade fairs in China. It will connect the hotel and catering industry chain, and assist the national caterers and service providers to introduce various products and services.

▲ Previous CRE site photos

With the increase in the depth and breadth of the promotion of "plastic restriction" , the food and beverage packaging industry gradually began to replace traditional disposable tableware with biodegradable products, such as coated paper Cups, paper bowls, biodegradable plastic bags, PLA biodegradable straw, biodegradable plastic knives, forks, spoons and other environmentally friendly products, these have been gradually on the "stage of history".

As a well-known brand of biodegradable materials, eSUN has rich and mature experience in research, development, production and sales of biodegradable packaging materials and products. This week, we will also bring biodegradable materials and a variety of packaging products appear to help the hotel catering industry healthy development! Welcome new and old customers to visit and communication!

Invitation to the fair

Name: 12th CHINA RESTAURANT EXPO

Time: May 21-23

Exhibition Hall: Area C, Guangzhou International Convention and Exhibition Center

Company: Shenzhen Esun Industrial Co.,Ltd

Booth number: 14.1 Hall BT25B

Introduction of eSUN's key products

Part 1 Biodegradable coated paper and products

Five Characteristics of eSUN PLA Paper Cups

Material environmental protection: Polylactic acid (PLA) coated paper replaces polyethylene (PE) coated paper. PLA is a biodegradable material, which is made by fermentation of agricultural crops such as corn. The production process of PLA is pollution-free, biodegradable and recyclable in nature, making it an ideal green polymer material. It is in line with the global and national environmental policy of plastic restriction and ban.

Material safety: Polylactic acid has good safety performance. Polyethylene (PE) coated paper may be oxidized to carbonyl compounds during the process of melting or applying it to the cup paper, and the cup may emit peculiar smell when poured into hot water. Polylactic acid coated paper has no peculiar smell, and has certain antibacterial and anti-ultraviolet properties.

Material resistance to high and low temperatures: Polylactic acid (PLA) coated paper has good resistance to high and low temperatures, and will not leak or deform when made into cold and hot liquid containers. It has good strength and heat-sealability, and meets the requirements of coated paper cups.

Uniform coating layer: The polylactic acid coating layer is uniform, flat and smooth, and has a good feel. It has excellent quality such as increased adhesion and gloss.

Water and oil resistance: Polylactic acid coated paper has the characteristics of traditional polyethylene (PE) coated paper to block water and oil.

Part 2 Biodegradable film blowing materials and products

eSUN can produce all biodegradable blowing film materials independently. The biodegradable film blowing material is a kind of alloy material based on biological material. Films of various properties and specifications can be made by blowing film or casting process for various types of packaging, such as fresh goods, express packaging, etc.

Properties:

A. Easy to blow film, good processing performance,It is suitable for ordinary LDPE film blowing equipment.

B. 100% biodegradable and compostable, according with EN13432 and ASTM 6400.

C. Compliance with food safety and hygiene standards.

D. A variety of formulations, corresponding to different characteristics and performance, can meet different needs of customers. Film stiffness, transparency can be adjusted according to requirements.

E. The film made by this materials with good air permeability, good printing performance . The heat seal strength can reach more than 10 MPA.

Application of biodegradable blown film products:

A. High heat sealing biodegradable film

B. Heat sealable transparent PLA film

C. Home compost film

D. Transparent biodegradable film for paper plastic coating

E. Special biodegradable film for paper plastic coating

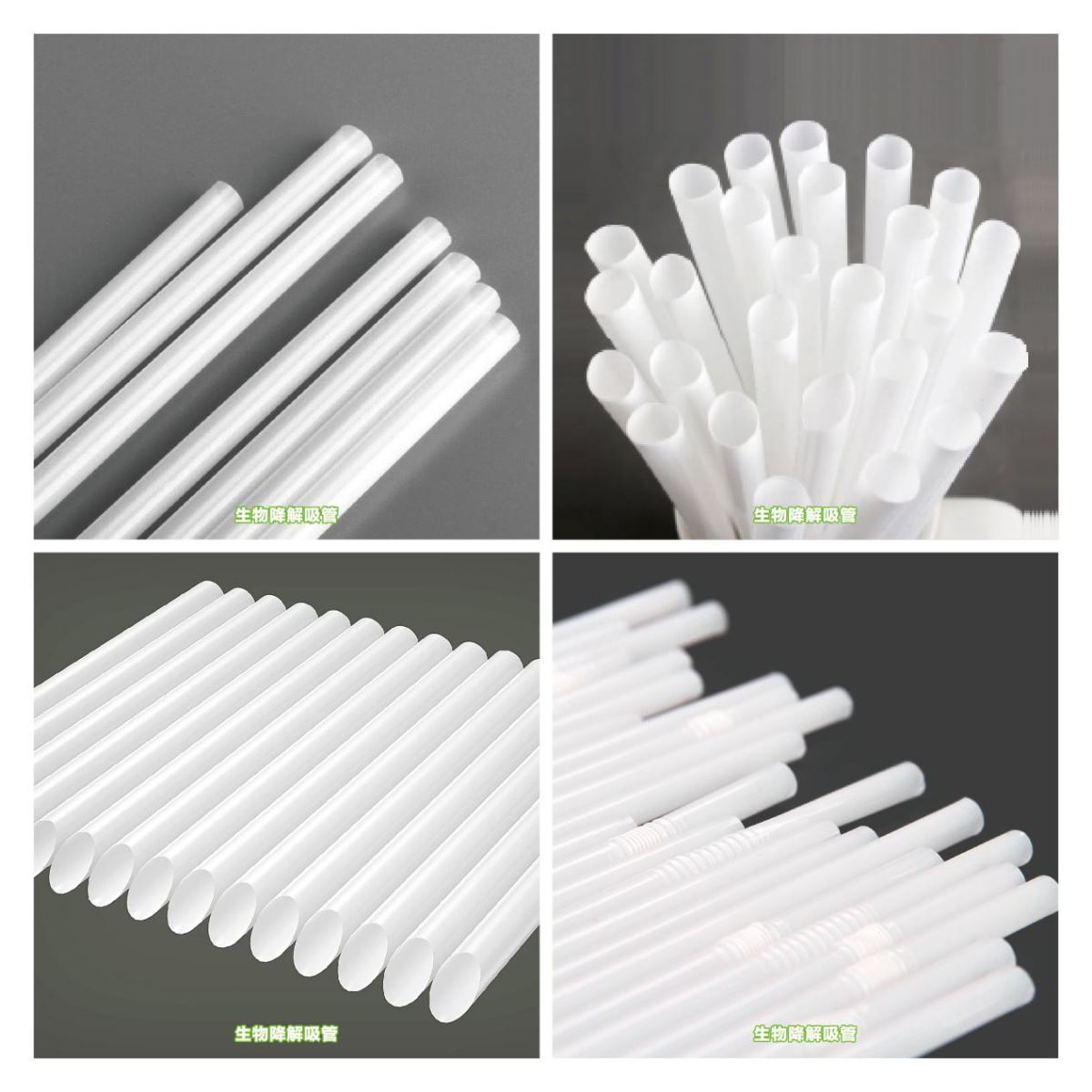

Part 3 Biodegradable Straw materials and products

Plastic straws, the first plastic dishware to be restricted in use, have been hotly debated by consumers several times this year. Based on the market demand, eSUN has launched a popular poly-lactic acid straw, its raw material comes from plant starch. Matrix material has a wide range of resources. With the high price of crude oil and the depletion of oil reserves, PLA drinking straw has obvious environmental advantages and social benefits, and will gradually replace the traditional polypropylene drinking straw.

PLA straw properties:

1.It is derived from plant starch such as corn and is 100% biodegradable material.

2.Comply with EU EN1343 and US ASTMD6400 standards.

3.The material is safe and healthy, and can be used in direct contact with food for hot and cold drinks.

4.The material is environmentally friendly, and the biodegradable straw can be 100% biodegradable after use, without environmental pollution.

Part 4 Biodegradable injection plastics and products

Properties:

1. Non-petroleum-based biological materials, low-carbon environmental protection, renewable resources, save oil resources

2. Good Mechanical properties, high rigidity and impact resistance.

3. Good processing performance, wider process range, easy to shape, constant nozzle, faster cooling and shaping, easy demoulding;

4. Good surface gloss.

5. Low shrinkage, good stable dimension.

6. Resistant to a variety of solvents, easy for dying and printing.

Application:

Biodegradable plastic injection molding products are mainly used in general, can be used in electronic and electrical products, catering supplies, stationery, household products, cosmetic appliances, mechanical engineering parts, toys, cars and other fields. Such as keyboard, mouse, mobile phone cover, electronic clock Shell, U disk shell, calculator shell, instrument shell, printer shell, pen-holder, ink box, cosmetic eyebrow pencil, cold drink cup, toy parts and Shell, car door handle, rear view mirror shell and lamp shade, switch KNOB, etc .

Part 5 Biodegradable sheet materials and products

Properties:

1. 100% bio-based, according with EN13432 and ASTM 6400.

2. High melt strength and thermal stability.

3. Easily process,higher process efficiency, high-yield, can be processed in common PET sheet processing equipment. It can be made into transparent sheet and non-transparent sheet.

Transparent Sheet Application

(1)The transparency of the transparent PLA sheet is high, close to the traditional PET sheet, can be made into a variety of plastic products, easy to observe the product inside the box, beautiful and generous.

(2) Can be made into disposable vegetables, salad boxes, fresh fish trays, etc., security guards, widely used in supermarkets, food stores and so on.

(3) Can be made into disposable transparent cups, juice cups, etc., for home and juice shops.

(4)Can be made into a plastic product packaging blister..

Non-transparent Sheet Application

(1)The opaque sheet has good toughness and can be made into different colors according to customer requirements.

(2)Clothing accessories, such as shirts and collar substrate.

(3)Can be made into electronic product trays.

(4)Used on toughness to demand higher membership card,magnetism card, partly instead of PVC cards.

About us

Research on the modification and processing of biodegradable materials, and provide one-step technical service programs such as equipment,raw materials and proessing technology.

Please feel free to discuss with us and look forward to communicating with you. Or you can leave a message at the end of the next, we will get in touch with you as soon as possible!

Telephone: +86 755 86393186

Email: bright@brightcn.net

WeChat ID: GWWYeSUN