News & Media

Stay tuned for eSUN with 21 innovative products at Formnext 2019

2019-11-12

The German Formnext exhibition is a milestone in the global additive manufacturing and modern industrial production. Each session will showcase the diversified solutions of the world's latest material manufacturing. From the software creative modeling, digitization, pre-processing, to the simple processing of surface treatment, from product conception to industrial mass production, the entire process of additive manufacturing, can be found here.

☻ eSUN at Formnext, 2015

☻ eSUN at Formnext, 2017

☻ eSUN at Formnext, 2018

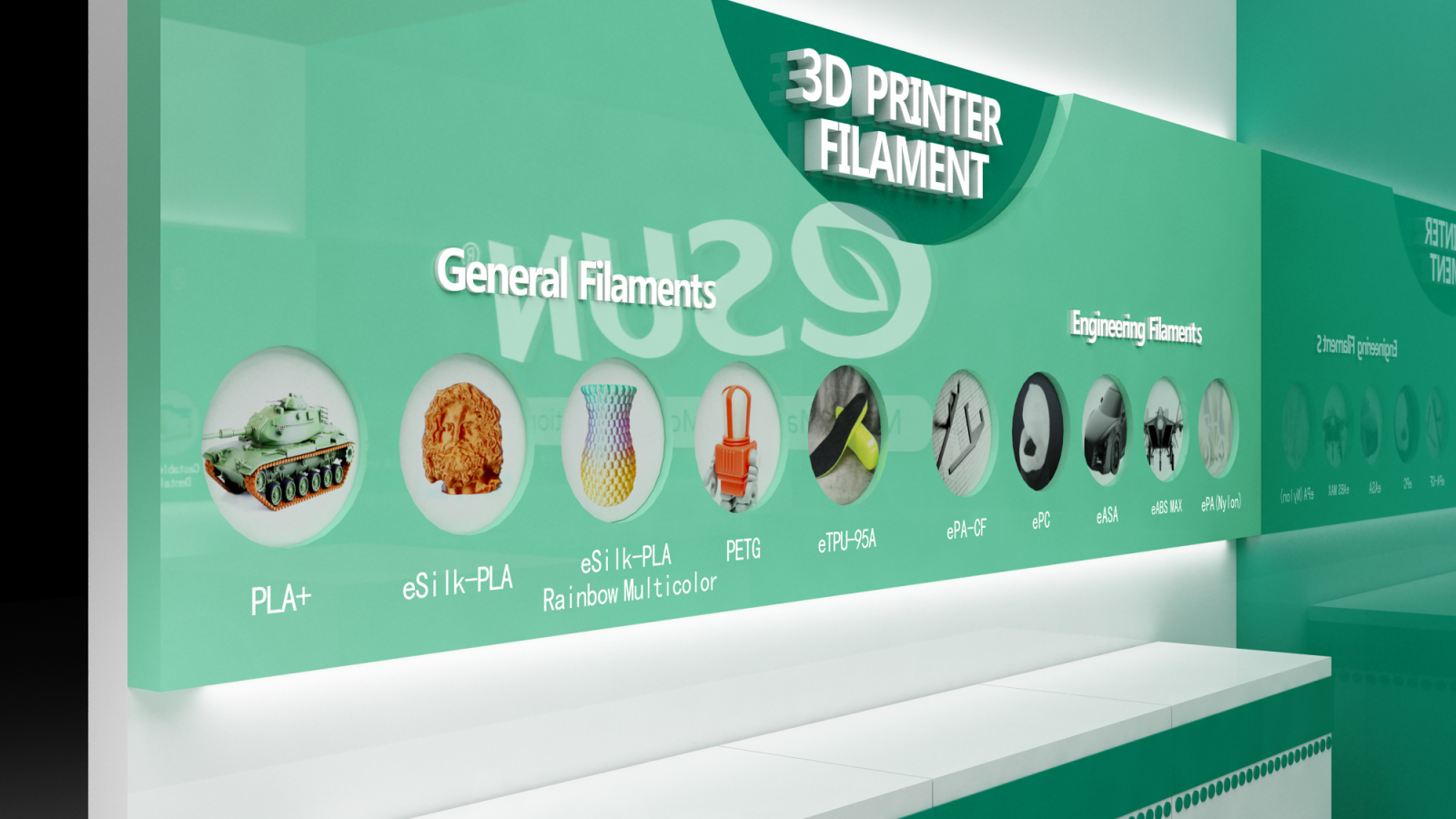

You don’t want to miss Formnext 2019 this year! At that time, eSUN team will bring the company's FDM 3D printing filaments, new best-selling photopolymer resin, cost-effective 3D printing equipment and 3D printing innovative application solutions to the international 3D printing feast.

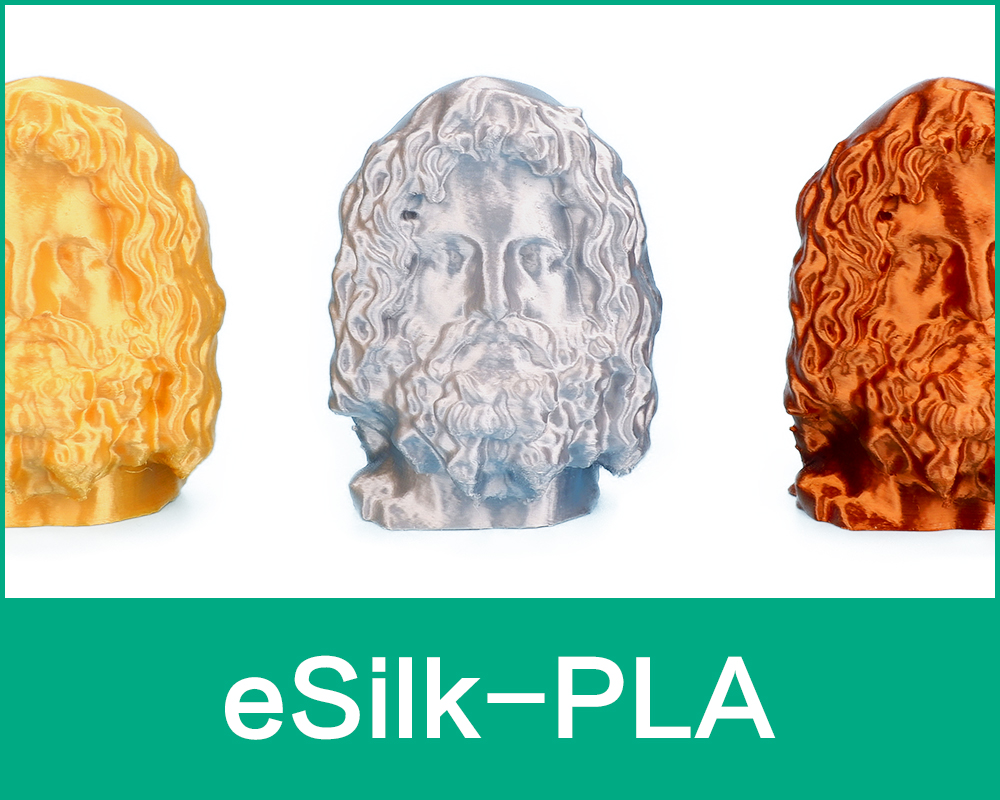

Biomaterial extracted from corn grain, naturally degradable and not harmful the environment; hard, strong and rigid; good gloss and transparency; printing process is non-toxic and tasteless, not warping or edging.

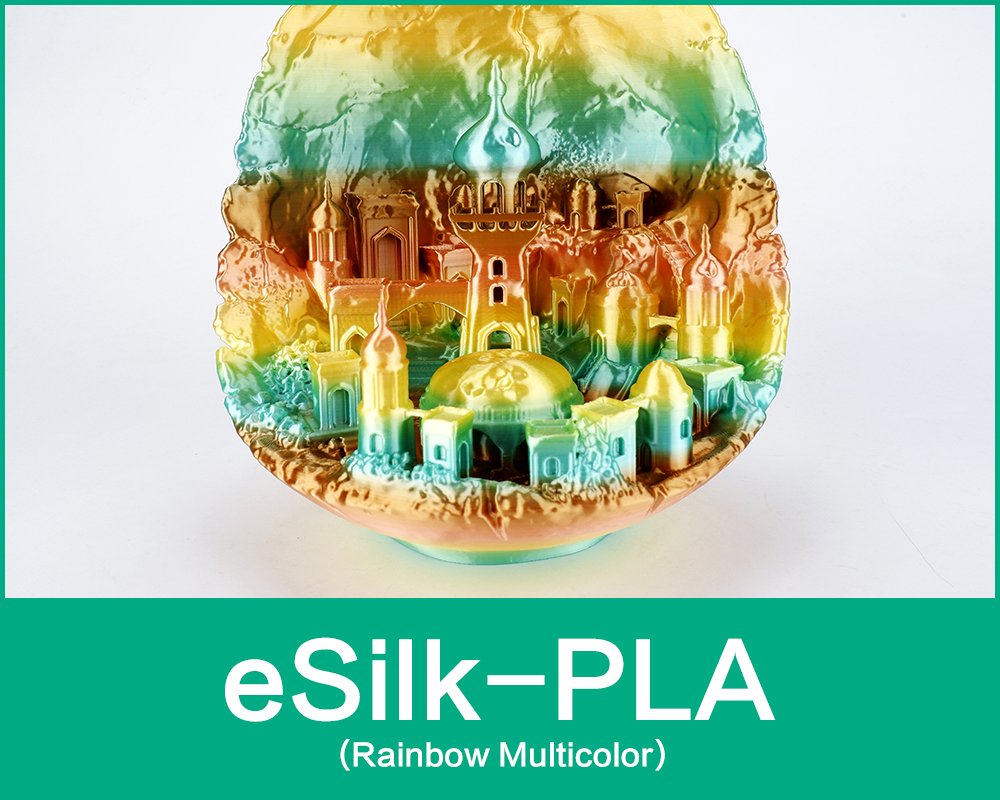

Same product as eSilk-PLA with the same performance, and this material comes with a rainbow gradient, 3D printed works can be colorful without dyeing.

The material is odorless when printing, good shrinkage, no warping, strong hydrophobicity, high transparency and good gloss; it has outstanding toughness and high impact strength; good fluidity, broad processing range and can be recycled, which is very environmentally friendly.

With its high flexibility and high resilience, it greatly reduces the permanent deformation rate of the material; it also has moisture permeability and hydrolysis resistance, flexibility and hardness are higher than similar materials, with high transparency to make sure that the print size and shape are stable; the material is environmentally friendly, odorless and tasteless, and the surface of the product is easy to paint!

ePA-CF_

ePC_

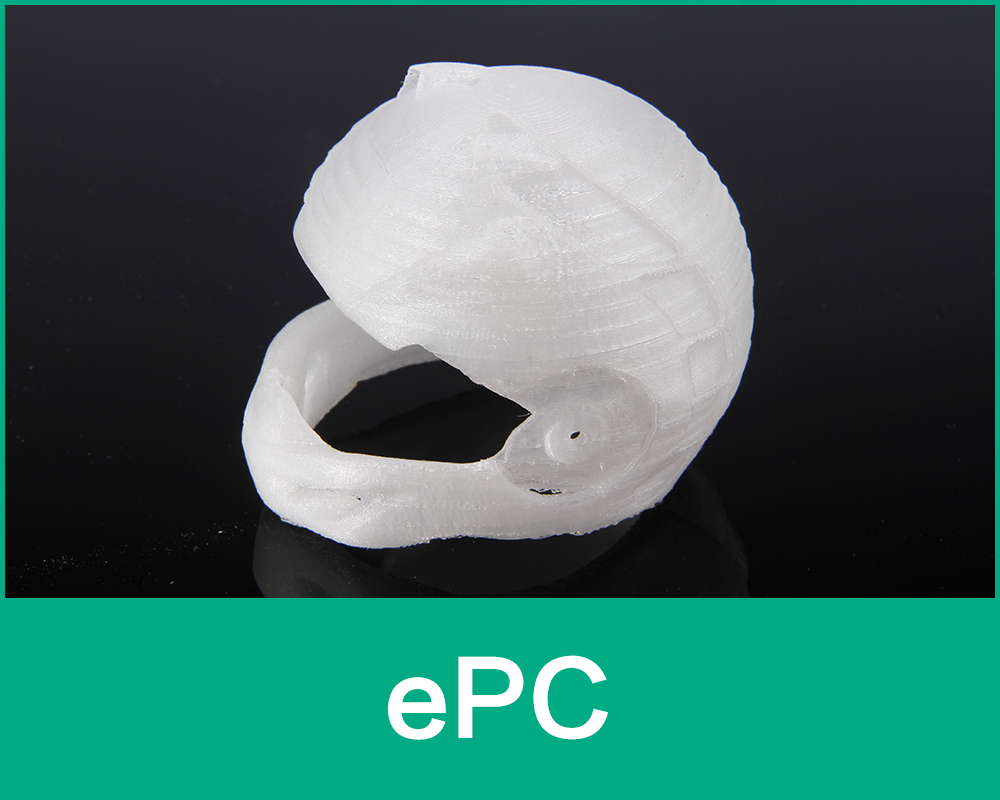

A non-toxic and environmentally friendly material that meets the requirements of conventional FDM printing compared to conventional PC filament. It has good high toughness and transparency, high temperature resistance, high flame retardancy with flame retardant grade of UL94-V2, which can play a certain role in fire prevention.

eASA_

Similar in structure to ABS, with excellent mechanical and physical properties; excellent weather resistance and UV resistance due to the replacement of butadiene with double bonds during polymerization; as an antistatic material with good high temperature resistance, it’s also dust-proof.

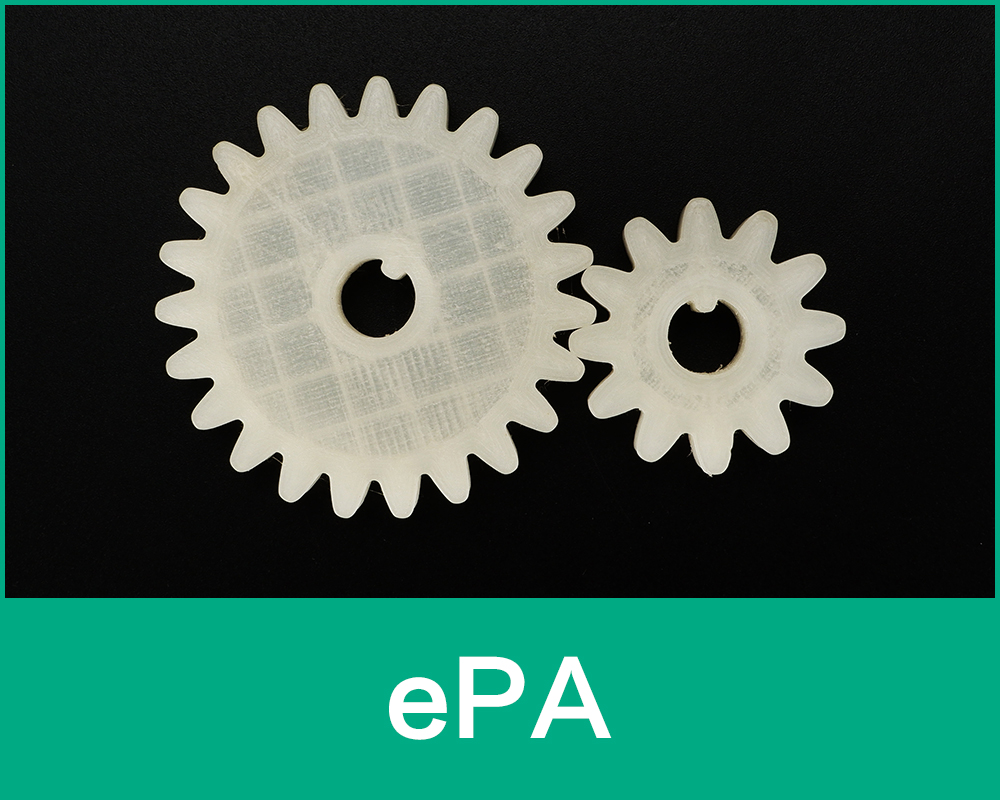

This product is non-toxic, hard and tough, has good temperature resistance and creep resistance, good melt flow, and oil resistance, can maintain about 90% physical properties at low temperature minus 20 ° C, no brittle, water-proof, and has a water absorption rate of less than 1% at normal temperature, ensuring a flame retardant effect, and the surface can be polished with acetone.

It has high temperature resistance that traditional materials doesn’t. The biggest feature is high flame retardancy, and it also has good chemical resistance, oil resistance, high toughness and wear resistance, making it suitable for a wide range of applications such as industrial parts, handicrafts, daily necessities, mold opening design and other fields.

The world's first bio-based resin, safe and environmentally friendly; high printing accuracy, good hardness, scratch resistance; good hydrophobicity, dry surface, not easy to absorb moisture.

Developed for prototypes requiring precision component parts, hardness up to 88D, very tough, good impact and strength, fast print speed, low shrinkage, and highly compatible with DLP printer with LED UV light source.

With the strength and performance of Standard resin, a preferred material in the process of product and product development; hardness 76D, high toughness and impact resistance; high precision, the printed model can be directly rinsed with water, no puncturing odor, safe, environmentally friendly, high surface precision, compatible with most LCD printers, is the preferred material for school and home education.

Specially developed for dental mold making applications, with low viscosity formula, super hardness and minimal shrinkage, suitable for making denture base, repair model, removable dental mold , orthodontic models, etc.

Formnext 2019

注明:本文章配图除项目图片均来源网络,如有侵权请及时联系。